This post is the introduction to a longer paper by The Switch, a manufacturer of permanent magnet generators and their support equipment.

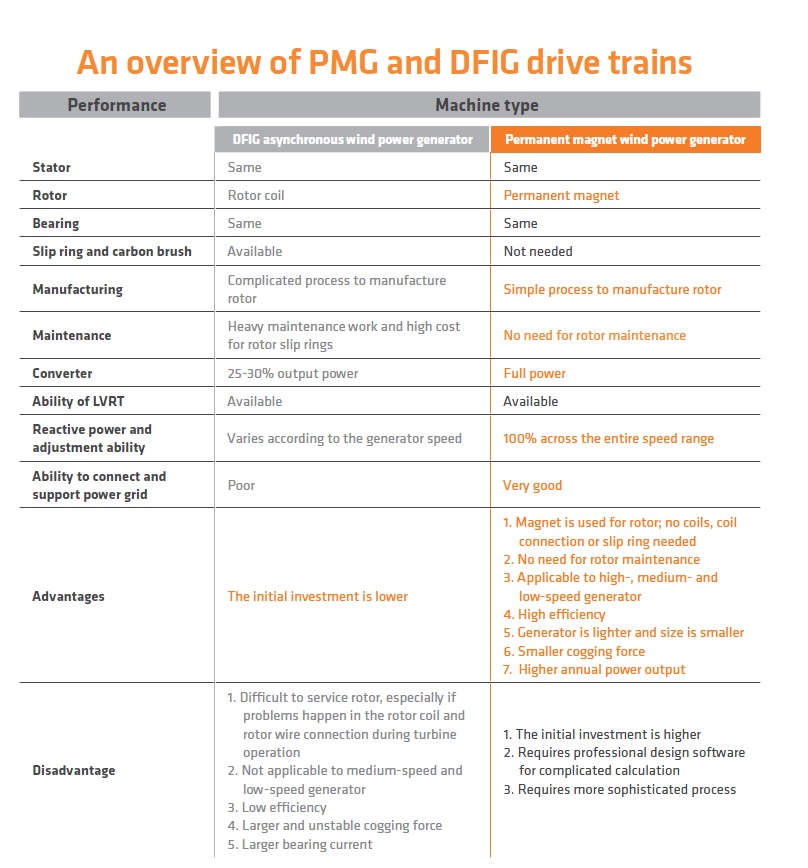

In the wind power industry, the debate on which generator and converter option makes for the best modern wind turbine drive trains is still raging. Numerous technology experts and industry commentators promote the use of the double-fed induction generator technology, while expressing doubts about the advantages of the permanent magnet generator (PMG) approach. In this paper, The Switch aims to set the record straight and explain why PMG with a full-power converter (FPC) is by far the best technology, regardless of which key decision-making criteria you use.

The total life cycle cost efficiency angle:

PMG-FPC drive trains offer higher total life cycle cost efficiency than DFIG drive trains

It is sometimes claimed that permanent magnet generator (PMG) and full-power converter (FPC) drive trains are more expensive than double-fed induction generator (DFIG) drive trains. However, research has established that when every investment and operational factor is taken into account, PMG-FPC drive trains work out to be a cheaper, more cost-effective option over the total life cycle of the turbine. The true costs come into play when connecting to the grid

The lower grid connection costs of PMG-FPC equipped turbines represent a significant advantage over DFIG models. Efficiency and grid compliance are top demands when it comes to generator selection. These factors, along with high annual energy production (AEP) and reliability, are very important from an investment point of view. While partial converters may have improved somewhat in grid code compliance, full-power converters remain the preferable option. As stated in the report, ‘Power System Architecture: Finding the Best Solution for a 5MW Turbine’, published by the engineering consulting company NextWind: “PMG is also a good choice for grid code compliance. Due to the full converter, all requirements for harmonics, power factor control, and grid fault ride-through can be met easily.”

DFIG technology now complies with the grid codes by adding hardware and software at the expense of extra costs. This is a simplistic answer to the problem, and is more of a quick fix than a concrete solution. With regards to DFIG, the NextWind study explains: “There is extra cost related to meeting new grid codes with the DFIG. With fault ride-through and power factor capability, the DFIG converter becomes similar in size and cost to the full converter.”

A key benefit of PMG-FPC drive train technology is the fact that it already includes features such as reactive power generation and low voltage ride-through (LVRT). These inherent benefits level the playing field when making comparisons with the cheaper upfront costs of double-fed induction generator drive trains, which also need additional VAR support to make a connection to the network.

The long-term advantage comes from the extra energy produced with the higher power curve efficiencies of PMG technology. The PMG’s maximized energy production is what gives significantly higher income and profitability. Research conducted by Peter Jamieson and presented in the report, ‘Innovation in Wind Turbine Design 2011’, showed that PMG-FPC drive trains produce more energy in low or medium wind conditions, leading to better income.

PMG-FPC drive trains actually improve efficiency over the full operational range of the turbines. Although some claim that DFIGs are more efficient than PMGs at full load generation and in high, steady winds, in reality, the efficiency of the PMG-FPC and the DFIG plus partial converter are similar when operating at 100% power. However, we know that this situation rarely occurs, and in general working conditions, PMG drive trains have proven to be more efficient. In fact, the lower the power, the lower the efficiency of the DFIG. In addition, the Ohmic losses in the DFIG winding due to the excitation power, which are more or less constant regardless of the output, also reduce the DFIG’s efficiency.

The full six page discussion is available from:

The Switch

http://www.theswitch.com/2014/03/20/pmg-vs-dfig-the-big-generator-technology-debate/

Filed Under: Generators, News