Malloy, a wind turbine bearings supplier, has completed phase 1 of its warehouse expansion project. This investment increases Malloy’s overall warehouse capacity by 35%. “By expanding our warehouse, we’re directly addressing the needs of our customers who rely on our bearings for smooth operations and minimal downtime,” said Cory Mittleider, wind business unit Manager at…

Timken to provide bearings for GE’s Haliade-X wind turbine

The Timken Company announced that it is designing and supplying main shaft bearings for GE Renewable Energy’s Haliade-X wind turbine. Each Haliade-X turbine will have a capacity of up to 14 MW and be able to generate up to 74 GWh of clean energy a year. Initial Haliade-X installations are scheduled to begin in 2023.…

New hardware from ONYX Insight predicts pitch bearing failures before they happen

ONYX Insight has launched a new hardware solution that predicts where and when costly pitch bearing failures occur in wind turbines. This type of failure is a significant problem in the wind industry. Pitch bearings connect the rotor hub to the blades and experience high loading during the life of a turbine. There are many…

The ELF not welcome in the wind industry

By David Clark, CMS Wind About 50% of drivetrain failures are in the generator, and they are predictable by months with the right detection. The failures are grouped into three specific categories: bearing-related, electrical-related and misalignments. Here we’ll discuss electrical fluting caused by an “ELF.” Stray electrical current is not a problem unique to wind.…

Sentient Science and Croda partner for wind turbine life extension

Specialty chemical company Croda International has announced a new partnership with Sentient Science for the recommended use of Croda’s Rewitec additives for wind turbine gearboxes and main bearings. In 2019, Croda acquired Rewitec GmbH and began to offer energy technologies customers nano- and micro-particle-based additives to increase the durability of machinery by lowering friction and…

Winding down maintenance costs in wind turbine generator repairs

By Mark Meyer, Sales Manager, North America at SIFCO ASC It is no secret that the wind turbine market is growing. Seen by many as the long-term answer to the future of power generation, the sector is expected to grow at a CAGR of more than 10% during the forecast period 2020-2025, according to Mordor…

System Seals releases new grease-pumping seal for wind turbine main bearings

System Seals, a research-based seal manufacturer focused on optimizing main bearing performance, has created a new grease-pumping seal that dramatically reduces maintenance and costs for wind-turbine main bearings. The Vortex is an innovative corkscrew-style seal that uses the turning action of a rotary shaft to pump grease back inside the bearing as grease tries to…

Extending wind turbine life with pitch bearing upgrades

By Corey Bayles, Senior Product Engineer, Renewable Energy Applications, SKF USA Extreme weather, unpredictable heavy loads, remote locations and designs for higher output are just a few of the operational challenges affecting wind turbines that can lead to unexpected bearing failures. Fortunately, wind turbine service life can be increased by upgrading design, components and technology.…

What to know when setting two-row tapered roller bearings in wind turbine gearboxes

By Kyle Smith, principal application engineer, The Timken Company The evolution of wind turbine gearbox design has resulted in the use of an increased number of tapered roller bearings throughout the parallel shaft section to effectively manage both the radial and axial loads produced by helical gearing during operation. This arrangement includes a cylindrical roller…

New grease from Klüber Lubrication reduces wind turbine bearing heat

Klüber Lubrication, a worldwide manufacturer of specialty lubricants, introduces Klübersynth BZ 68-400, a lubricant specifically designed to mitigate hot bearings in wind turbines. Hardened residues that accumulate on generator bearings can become a nuisance and prevent efficient operation. Most situations require cleaning by hand, or the wind power turbines must be curtailed which results in…

Liebherr signs supply agreement with Mingyang Smart Energy

At the international wind energy fair China Windpower in Beijing, Liebherr Components signed a cooperation agreement with the country’s leading wind turbine OEM Mingyang Smart Energy. Under this serial manufacturing contract, Liebherr will supply the customer with significant quantities of main bearings. This will further secure Mingyang Smart Energy’s long-term business success in the Chinese…

Upgraded rotor bearings offer improved wind-turbine efficiency

By Andreas Bierlein, Schaeffler Technologies GmbH & Co. KG, and Antonio Silverio, Schaeffler Group USA Inc. In an effort to increase the reliability, durability and efficiency of wind turbines, Schaeffler has upgraded its entire lineup of spherical roller bearings (SRBs) for the turbine’s rotor shaft. By using data compiled from 10,000 wind turbines, a thorough investigation…

Extending main-shaft bearing life in wind turbines

By David de Garavilla & Dr. Xiaobo Zhou SKF The renewable energy sector is being forced to reduce the levelized cost of electricity (LCoE). The wind energy industry is striving to match or exceed the LCoE of traditional energy sources. Due to the cost of the equipment combined with the lower relative operations and…

How to choose the right bearings for offshore wind turbines

By Doug Lucas; Wind Energy Engineer The Timken Company Onshore wind developers and operators deserve enormous credit for their hard work and dedication. If the U.S. is to fully optimize wind capacity in the country, however, it is time to follow the UK and European markets. And this means pushing the offshore wind sector forward…

Why sealing is one component of effective bearing lubrication

Effective sealing is a critical but, at times, overlooked component of effective bearing lubrication in wind turbines. In many cases, seals are the differentiating factor that impacts overall bearing and system performance. Consider that most wind turbines experience some amount of lubrication leakage. These occurrences are relatively minimal for onshore turbines but can pose an…

How SKF is letting data drive its decision-making

Only a few companies lay claim to a century of business and SKF is one with 112 years of history. Founded in 1907, the bearings and seals manufacturer was founded in Sweden. Within a couple of years, it formed branch offices in various European countries, including a subsidiary in New York. Today, SKF continues to…

Timken presents bearing solutions & power transmission products to reduce turbine downtime

The Timken Company, global provider of engineered bearings and power transmission products, has built a powerful portfolio of solutions aimed at helping wind-turbine operators and manufacturers improve the reliability of their assets and move the industry forward. The company will present its products and expertise at the American Wind Energy Association’s (AWEA) WINDPOWER 2019. “Timken’s…

Aurora Bearing publishes expanded catalog of product offerings

Aurora Bearing Company (Montgomery, Il), manufacturer of a complete range of rod end and spherical bearings, announced the availability of their latest product catalog. Aurora’s catalog 319 features their newest product offerings, as well as the quality legacy components the company has made. The new 128-page publication is a graphically enhanced technical resource that will…

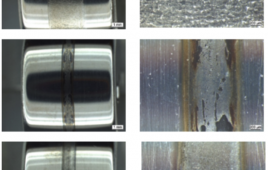

A coating for more reliable wind-turbine bearings

It’s been said a wind turbine is only as good as its components, and a turbine’s bearings are extremely important ones. Although bearings are used many places throughout a nacelle, such as on generators and in the yaw and pitch system, those on main shafts and gearboxes are typically most problematic. Not too long ago,…

New online tool makes bearing selection faster and easier

SKF has updated its online Bearing Select tool, to make the process of selecting and evaluating a bearing faster and easier. To use the new tool, designers access it online and enter relevant values for their design. The software then uses SKF engineering knowledge to evaluate bearing performance and calculate relevant results, such as rating…