Before wind projects are brought or sold, analysts familiar with such facilities often write 30 to 50 page reports – wind-resource assessments – on how they see the facility working. Frequently, there is more value in the report than one might imagine, information that might explain the difference between predicted production and actual output. That was the message from independent consultant Amit Bohara at the recent Wind Operator Congress. Bohara previously spent five years with DNV GL and GLGH supporting analysis on more than 50 projects.

“The wind-resource assessment report makes a lot of sense before sanctioning a buy,” says Bohara. “But is there also something else useful in the report if you’re managing the site? Yes. Sometimes it may be the estimates, such as the expected energy output of the site. Other times, estimates of expected wind speed variability or availability can be used as a benchmark to help evaluate how the project is actually doing.”

Questions he has been tasked with answering include: What is the long term energy potential? A lot of that deals with operational projects. “You want answers to such questions when a project has been acquired or refinanced. So when a better production estimate is required, even from one to two years of operational data, the report helps make a much more accurate prediction for the next 20 years,” he says.

Other questions the report might answer are: How much curtailment related downtime has the project experienced? Are the turbines working properly? This latter question may be answered by close scrutiny of turbine power curves, and can help detect cases where the turbine was not operating optimally due to pitch & yaw issues or incorrect control setting. “Another interesting situation arises after building an extension to a project. It would be useful to know ahead of time how Phase 2 might decrease Phase 1 production,” he says.

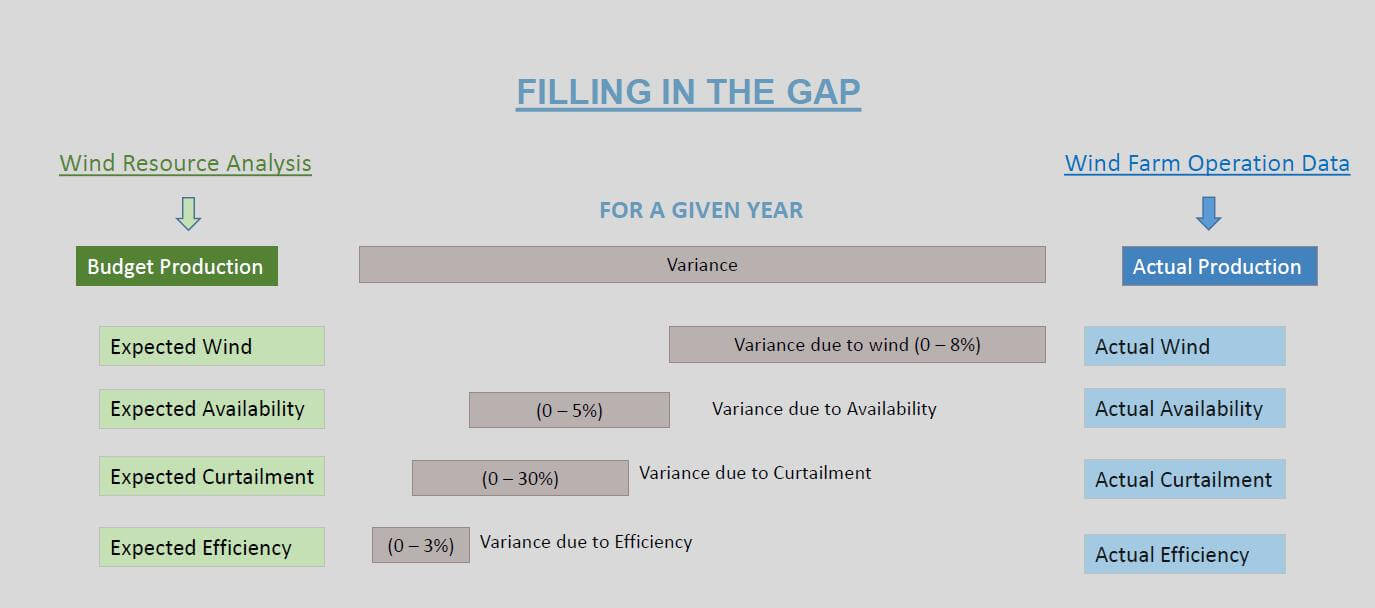

There will always be a difference between expected and actual production. But where does the variation, the gap, come from? A reasonable place to start is to compare production to the pre-construction estimates because that, to some degree, is what the financing is based on.

“Assume we have a site selected along with a general layout. What can the site produce? It’s a tricky question because there is no one answer. The answers always come in a range. So a better way to phrase the question is: How much production does this project have a 50% chance of reaching? Now you’re not asking for what the site exactly produces, but what can it at least achieve at some probability level. That is the P50 figure. It is the production a wind-resource assessment thinks you have a 50% chance of achieving,” Bohara said.

This same question can be asked at the different levels, such as P75, P90, and P99. “These production figures are trying to tell you the production you are able to exceed under different confidence levels so an organization can make the right decision based on their risk tolerance,” he said.

“For example, suppose a P50 value for a 100 MW wind-farm says production will be about 100 MW. “The number means that the analysis estimates that the Project has a 50% change of exceeding 100 MW of annual production over the long term. A P75 number could be around 94 or 95 MW, and so on. A P99 figure might say with great certainty, production will be at least 75 MW. The P-numbers provide a range of values and the different probabilities of exceeding them,” said Bohara.

A P50 estimate represents the production (based on an energy assessment) the wind project is most likely to achieve (though investors can often chose to invest at different P-levels depending on their risk tolerance). The P50 from an operational energy assessment (or a pre-construction assessment) can be a reasonable benchmark for assessing your wind project production. However, while the P50 estimate is a fixed number, the actual production will likely vary due to influences from wind, availability, turbine operation inefficiencies etc. Understanding the cause of this variation can help keep the wind farm operation on track.

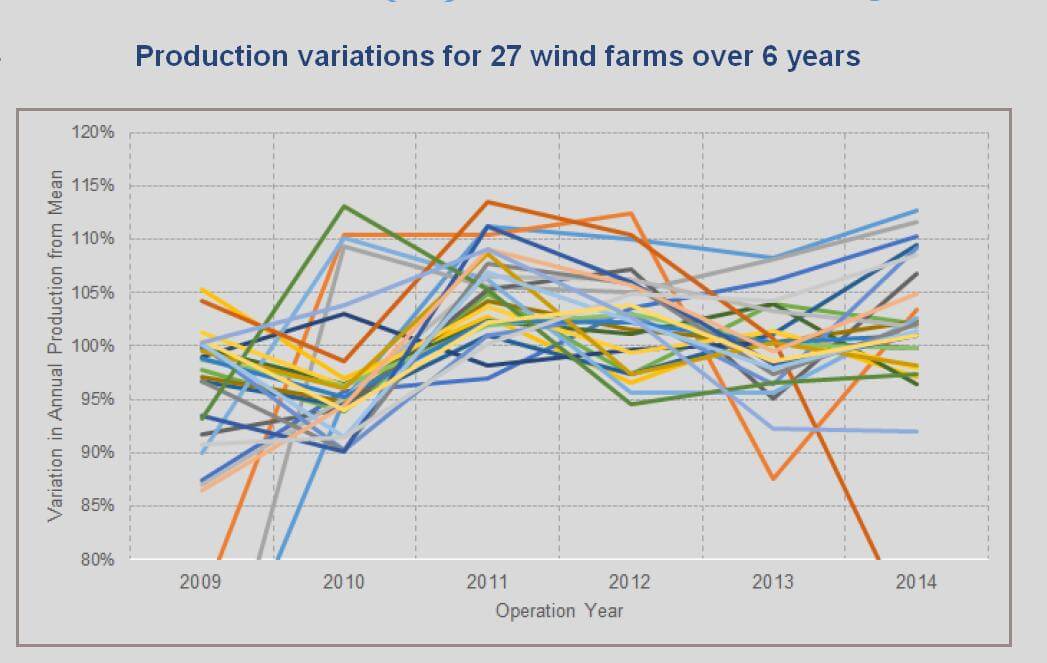

Variability is a natural part of energy production in a wind farm. For example, Production variations for 27 wind farms show the outputs from the farms from 2009 to 2014 relative to their 5 year mean. Look at the variability and what they produced. Here is the big question: When assessing recent production, how do you know that the changes observed are expected changes from the wind, and not because of anything else?

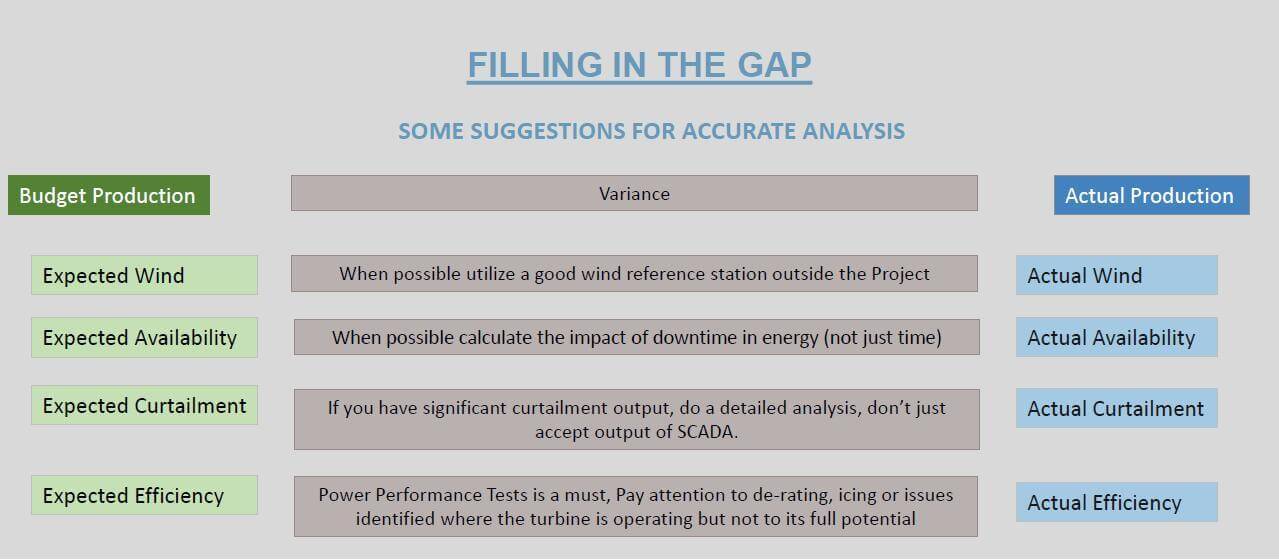

To approaching the problem, start by comparing the actual production of the wind project to the expected production level. “The expected production level may come from an energy assessment while the actual production is best obtained from a utility meter at the grid interconnect. Try and develop understanding of what is driving the variation between the actual and expected production level. It is a good idea to make the comparison on a yearly basis. If you can, do it quarterly and you will just be able to better respond to things,” he says.

The expected production level derived from an energy assessment analysis takes many factors into consideration though roughly down into four independent contributing factors. First, the most important factor affecting the project production is the sites wind levels. Second, the expected availability – how often the project is available to produce energy. It is important to consider the effects of both the turbine component failure as well as downtime that may result from the balance of plant and environmental factors. Third, there may be curtailment imposed on the project that leads to energy losses , however, the impact of which can be minimized if there is a compensation structure in place.

Fourthly, turbine efficiency. There are two aspects to it. “One is what the manufacturer says in the power curve which can be tested with a power performance test. The other is efficiency losses that can result from operational issues such as icing , derating, blade degradation, and so on,” said Bohara.

A wind-resource analysis should give a good starting estimate for how much the wind can change in your particular place. Some of such numbers range from 5 to 6% from year to year, on average.

“The second thing to notice is how much of the variance is coming from availability. I have seen somewhere in the 1 to 5% range,” says Bohara.

Curtailment is an interesting issue because it appears as downtime or a de-rating, depending on the kind of curtailment at a site. When more than 5% of a site’s annual time is due to curtailment, do a more detailed study. “If you think you’re annually losing 10 gigawatt-hours, the figure could easily be closer to 60. The science of wind flow is different when things are curtailed at a massive level, such as an entire wind farm,” he said.

Lastly, efficiency needs a close look. “When completing a wind-resource analysis, assume you’re going to work with SCADA data, the turbine power curve, and maybe with adjustments for different degradations,” he said. For example, examining SCADA data may reveal icing losses in the winter, or someone de-rated the turbine and forgot to turn it back up. Make sure items of this sort are not overlooked.

“Now just a few comments on what can improve an analysis when you’re looking at each of the factors mentioned. Wind, of course, is the biggest factor. It is the biggest contributor as to why the production may vary so much. One way to get a better sense of wind resource variation is to look meteorological station that comes are nearby or regional but not necessarily directly from the wind farm. For instance, when there is a met mast on site, it is “waked” by the turbine on site and may not provide an independent measure of the wind. In such cases, you might compare (a met mast) to a regional weather station or a reanalysis data set such as MERRA , which is a data set that NASA distributes. It’s a neutral source and it’s not affected by the turbine. You might use it as a benchmark to understand for how the wind is changing.

There is one other thing in wind that affects a site. It is a sensitivity filling factor, and that says for every 1% change in wind, turbine performance changes by more or less than 1%. It is not a 1-to-1 relationship all the time. This value is often provided in an energy assessment report.

Availability is one thing that everybody is paying attention to. “It’s easy to get caught up in just what the turbine availability is, but you can lose track of where you’re losing energy in other places. There may be downtime resulting from environmental factors such as icing or Balance-of-plant outages. When trying to reconcile these things, consider all sources of down time, not just the turbine. If you can, it’s always good to calculate the actual energy loss, not just the time, due to down time,” he said.

Should you find a persistent gap after years of operation, and with no suitable explanation for the variance, it may be a good time to do an operational assessment. An operational energy assessment will use the latest production data to re-calibrate the long term expected energy level and provide the most accurate estimate for production for future years.

“An operational assessment differs from a pre-construction wind assessment because it relies directly on the production figures while a pre-construction assessment will utilize local met-mast wind measured coupled with simulation to arrive at production figures. The latter has a higher uncertainty due to complexity of wind measurement and modeling of wind flow as well as wakes. Conducting an operational assessment involves taking one or more years of actual data, correcting it for availability or identified performance issues, and projecting it into a 10 or 20 year history,” he said.

Reach Bohara at amitbohara@gmail.com

Filed Under: Financing, News