The Titan platform is engineered to support a single wind turbine in water depths greater than 48 feet.

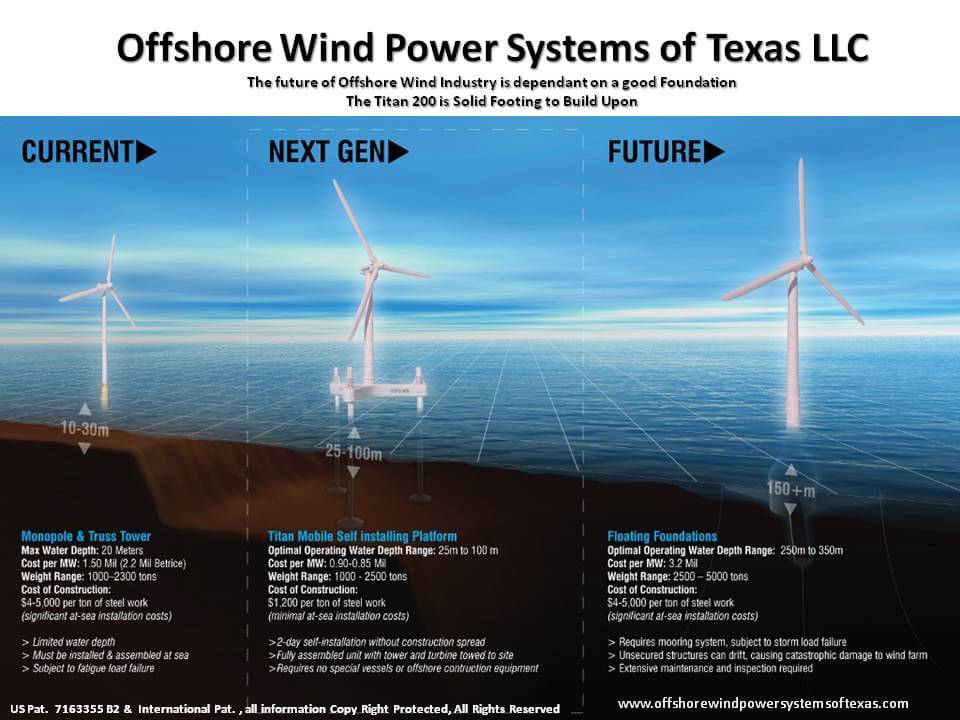

With stronger wind speeds available offshore than on land, wind developers are eager to take advantage of them. However, pile-driven foundations conventionally used to support turbines in shallow waters do not hold up as well in deep waters. Designing a foundation reliable enough to withstand the rugged offshore conditions has been a challenge for the wind industry.

Rather than reinventing the wheel, engineers at Offshore Wind Power Systems of Texas looked to another industry that’s already experienced in deep-water and ocean bed work: the offshore oil industry. Platform and jack-up systems have commonly been used in the offshore oilfields since the 1950s. After a rigorous review of numerous drilling rigs, the Texas firm designed the Titan 200 Offshore Wind Platform.

Using newly patented jacking technology, the Titan is an offshore jack-up substructure composed of a unique Y-shaped hull that’s slightly smaller than the radial diameter of the wind turbine’s rotor. The Titan platform is engineered to support a single wind turbine in water depths greater than 48 ft. (six fathoms).

What makes the platform particularly efficient and economical for the wind industry is that it’s first assembled on land (with turbine installed), and then towed to the offshore site. This eliminates need for costly cranes or barges and onsite construction. During transport, the platform acts as a barge and floats with raised legs that won’t overturn even in rough waters. If an arm of the hull starts to sink, the weight of the other two arms bring the platform instantly back to horizontal (known as a Dutch tri-floater design).

Once onsite, the hull and turbine are raised together to stand on three legs using a jacking system capable of lifting the entire system well above the surface of the water. Each leg is independently adjustable and can accommodate a range of irregular seabed soil or rock conditions, including exposed bedrock. Should the turbine need repairs at some future date, the legs are again raised and the platform can be towed to a dock or repair yard.

After the platform is firmly installed, the jacking system is removed and used to set the next turbine in place, which further helps to optimize installation costs.

The Titan 200 was designed to solve the deep-water dilemma of offshore wind foundations and at a price point that lowers the per-megawatt cost of an offshore turbine. Developers say it can withstand extreme storm conditions, including Category 5 wind speeds and wave heights greater than 25 m.

However, what makes the Titan unique is its ability to address another dilemma that has plagued governments and disaster relief agencies for years. That problem is the ability to deliver clean drinking water to coastal populations with chronic water shortages or to those recovering from the effects of a natural disaster.

The Titan can act as a self-sufficient, fully operational water producing plant. The developers maintain that a five-platform configuration — with four 2-MW turbines, 36 desalination units, and a fifth platform acting as a control station — is capable of producing enough water to serve the daily needs of a population of up to 99,000 people.

The Titan FWSS System can produce water and power in combination or alternately depending on demand. Water can be transferred to inland locations via pipeline and pumping systems located within the platform.

Filed Under: News, Offshore wind, Projects

Im Electric Eng. Great energy project