Particle counter manufacturer Pamas says its equipment can count particles online and offline, without pressure or under high pressure, and in the laboratory or in the field. The company says it has been manufacturing automatic particle counters for fluids for 25 years.

S40 particle counters have been developed for jet fuel and for water based hydraulic fluids that are mainly used in the oil & gas sector.

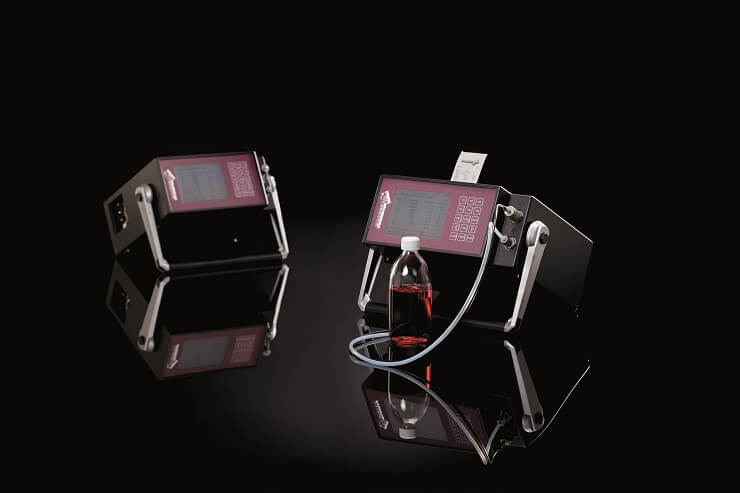

The compact and convenient instruments tell users within minutes if and to what extent a sample fluid is contaminated. The particle analysis technique is based on an optical measuring principle: light sensors detect and count contaminants in a liquid. Over the course of the last 25 years, Pamas has been perfecting this technique and implementing additional options and features. An example of this versatility of particle counters is in the S40 product series.

In addition to standard particle counting of sample bottles in a laboratory, the Pamas S40 particle counter can also be used for online sampling. For online measurements in the field, the particle counter is integrated into a system in operation (e.g. an ongoing hydraulic or lubricating oil system). A sample of the operating fluid is extracted from the system by a bypass valve and drawn into the particle counter. With this method, the user can verify in-situ if the sample meets or exceeds the pre-defined contamination cleanliness level.

Pressurised fluids and harsh environments do not affect the particle analysis with a Pamas S40: Due to an integrated pressure reducer, fluids can be measured under high pressure. For particle counting in the field, the instruments are available in a rugged case that protects from harsh environment.

Practical orientation and a close cooperation with the end user turned out to be of great benefit for the development of particle counters. With the end user, the company began to develop individual solutions for specific applications. For example, an aviation customer wanted to analyze a corrosive hydraulic fluid so Pamas developers built a particle counting system out of chemically stable components. The material was not affected by the corrosive sample liquid. This specific solution matured into a new PAMAS S40 product version which has been tried and tested for other applications with corrosive liquids and is available as part of our product versions.

Further product versions of the S40 have been developed for jet fuel and for water based hydraulic fluids that are mainly used in the oil & gas sector. For these applications, the particle counting results were brought into the industry-related format which is commonly used within these industries, so the user does not need any further software to convert the results. For users in the oil &gas sector, the particle measuring results are reported according to the SAE AS 4059 or NAS 1638 standards, and for users in Russia or China as per GOST 17216 or GJB 420.

Portable particle counters of the S40 product series are now available in a multitude of adapted product versions for the cleanliness control of oil, fuel, Skydrol, and water based fluids. A short video clip on the company website presents the main features of this product series. The video can be viewed at www.pamas.de after selecting the product page of the Pamas S40.

PAMAS will be exhibiting its particle counting instruments at the Motion, Drive & Automation show, taking place within Hanover fair in April 2017 (Booth No. A47 in Hall 23).

Filed Under: Filters, News