ABB will install its PowerStore, an integrated commercial flywheel and battery system, in Alaska to enable the integration of more renewable energy from a wind farm.

Since the invention of the potter’s wheel, flywheels have helped smooth the flow of energy in machines. Over time, more modern devices have found their way into some buses, trains, cranes, and automobiles, typically in the form of regenerative braking. In these cases otherwise wasted energy, say from a vehicle decelerating or stopping, is captured and converted into usable power.

A flywheel works by accelerating a rotor to a high speed. The energy is temporarily stored as rotational or kinetic energy. This power can then be converted back to a useful form in which it, for example, starts the vehicle moving again. .

For example, Volvo experimented with their S60 sedan a few years back, wherein rear-wheel braking would spin up the flywheel, producing mechanical energy that, upon later acceleration, would also help the move the car forward. Impressive, right?

How fast do modern flywheels spin?

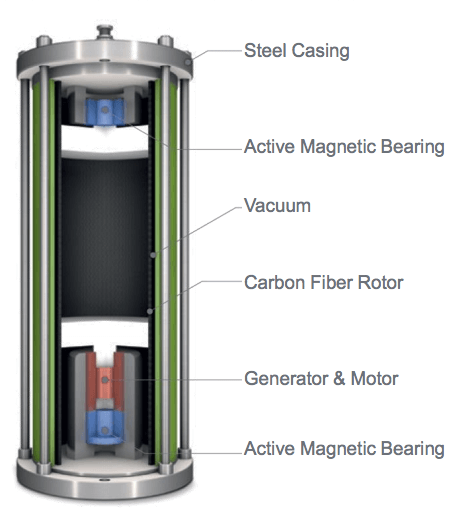

Thanks to recent advancements, flywheels have piqued the interest of some utilities and energy storage companies. Once made of steel, flywheels were limited to a revolution rate of only a few thousand rpm. Modern flywheels are made of carbon-fiber materials, employ magnetic bearings, and can revolve at speeds up to 60,000 rpm or greater.

Devices developed for energy storage are housed in an evacuated enclosure to reduce aerodynamic drag. The flywheel is also charged and discharged electrically, using a generator connected to the rotor.

Why do flywheels interest utilities or transmission grid operators?

For one thing, it is the ease and speed at which flywheels can hold and generate power. Grid balancing is typically achieved by conventional power generators, which must provide ancillary services such as reserve capacity. And for real-time load balancing, such as frequency and voltage control, the speed at which a generator can ramp up and down dictates distribution and value of the provided energy service.

STORNETIC’s EnWheel is made of high-tech material that lets the rotor reach speeds of up to 45,000 revolutions per minute. According to the company, this is achieve by reducing frictional losses to a minimum. The entire rotor runs in a vacuum, on non-contact bearings, and is made of carbon-fibre-reinforced plastic.

Flywheels can help with those functions. A high-quality device can quickly provide real and reactive power, both critical to balance power fluctuations caused by conventional loads or renewable energy sources. This makes flywheels ideal for helping balance variable power generated from wind or solar farms, improving grid power quality, and stabilizing voltage levels at the local distribution.

Wind-farm owners are, of course, at the mercy of the wind. Too much and too little impacts the grid it feeds into, and this is where energy storage comes in. Storage can help support and balance grid the integration of renewables.

Where batteries, such as lithium-ion, provide one answer for storage, absorbing and releasing energy within seconds and minutes, flywheels can match and exceed the capability of batteries. And, unlike lithium-ion batteries, flywheels do not degrade even after thousands of cycles so their operational lifetime can better match that of wind farms.

Are batteries and flywheels an either-or selection?

Flywheels can work in conjunction with batteries. For example, power company ABB offers a modular microgrid system that blends the complementary capabilities of both devices, which it is currently bringing to a 17-MW wind farm in Alaska. The flywheel will facilitate the integration of fluctuating wind power and a battery will be used for long-term storage.

Storage company, STORNETIC, points to the environmental benefits of a standalone flywheel system that include no toxins or chemicals. STORNETIC first introduced its EnWheel, a fully recyclable flywheel energy device, at the 2016 WindEnergy Hamburg event in September.

Within STORNETIC’s EnWheel flywheel device, a motor spins a carbon-fiber rotor up to a frequency of 45,000 revolutions per minute. This means the circumference of the rotor is moving at about 3,000 kilometers per hour. To minimize friction and maintain the high speed, the rotor is levitating on magnetic bearing in vacuum.

STORNETIC recently launched its first megawatt-scale energy storage unit. The DuraStor(R)1000 flywheel-based unit comprises of 16 EnWheel devices and enables users to transform electrical energy into rotation energy and store it, quickly and easily. (PRNewsFoto/STORNETIC)

According the company, a reliable flywheel system provides a gateway to more stable wind farms because it provides a predictability that is typically missing at wind projects.

“EnWheel, for example, allows absorbing output peaks , thereby making the output of entire wind farms more even and predictable,” stated the company’s Managing Director, Dr Rainer vor dem Esche, in a press statement. “It also enables a wind farm to provide frequency control services, to help balance the grid.”

STORNETIC is currently partnering with renewable developer, EDF, on a joint pilot project in France to assess the performance of flywheel energy storage technology and its affects on grid.

What other companies are working on flywheels?

A company called Amber Kinetics for one. An independent study recently released by California’s Emerging Technologies Coordinating Council concluded that the flywheel energy storage technology (FES) from this research and development company provides a four-hour discharge and that it successfully and effectively shifts power loads.

Amber Kinetics has developed new technology that extends the duration and efficiency of flywheels from minutes to hours, resulting in more economical and reliable storage for utility-scale applications. Learn more about how flywheels work by watching their video here.

Last year, Amber Kinetics signed an energy services agreement with Pacific Gas & Electric Co. for 20-MW of storage using its Gen-2 Flywheel Systems. It is one of the largest ever for a transmission-level flywheel system.

Furthermore, authors of the California study stated that using “this emerging technology on the supply side would provide the grid with more flexibility and load regulation opportunities,” and recommended it for adoption into California’s Self-Generation Incentive Program.

What advantages do flywheels have over batteries?

Amber Kinetics believes its steel flywheel technology will drive down pricing while enhancing operational safety and flexibility for utility-scale energy storage. Part of the cost savings comes from low maintenance intervals, particularly compared to batteries. The flywheels are manufactured from raw materials that exhibit no degradation and rarely require replacement.

“Because they are 98% steel by weight, they pose no risk of fire, chemical explosion, or hazardous materials release, and offer unlimited cycling during a 30-year lifespan,” Amber Kinetics’ Chief Executive Officer, Ed Chiao, pointed out. “Our vision is to provide cost-effective, flexible capacity for utilities looking to use storage to reduce costs and integrate renewable resources,” he added.

It will be interesting to see if more utilities respond in the U.S. by piloting flywheel storage projects of their own.

Filed Under: Energy storage, News