On the 8 January, preparations started for the installation of one of the tallest wind turbine towers in the world, designed by the Spanish company Nabrawind Technologies, S.L., (NBTECH) in Eslava (Navarra, northern Spain).

The objective of this project is to use a full-scale prototype to validate a new innovative design and assembly process, which removes the need for large and high-cost cranes currently used by the industry. Once installed, to validate its durability and performance, a fatigue test will be performed on the prototype that will simulate 25 years of real-life conditions in only 6 months. “With this test, it will confirm in an accelerated way the performance of the tower in operation. This will improve the reliability of the structure and minimize any technical risks before the first pre-series,” says Ion Arocena, Head of the NBTECH Tower Program. This is achieved by using a novel system that generates loads on the upper part of the tower, by oscillating it in a controlled manner, to simulate in a short time frame real-life conditions of a tower in operation.

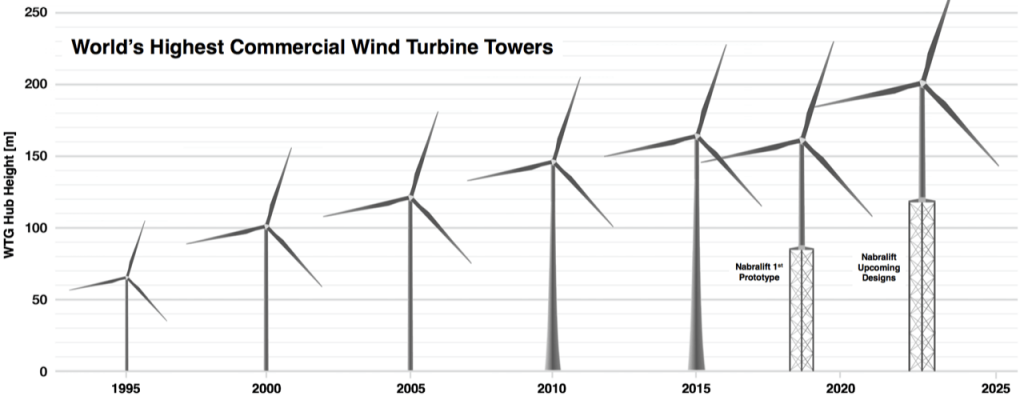

The new structure with its self-erecting system, which doesn’t require the use of large cranes, will enable the tower to reach heights of up to 200m in the coming years.

This test method, never performed to date on a wind turbine tower, was formulated during the NEVA project. The project is a collaboration with the National Renewable Energy Center of Spain (CENER) and financed using FEDER funding from the Spanish Ministry of Economy, Industry, and Competitiveness.

The tallest wind turbine tower, outside of Germany

The new structure with its self-erecting system, which doesn’t require the use of large cranes, will enable the tower to reach heights of up to 200m in the coming years.

However, to be in line with the current market situation, NBTECH has set the height of its prototype to 160m. Despite this, it will still be the tallest wind turbine tower installed outside of Germany.

Therefore, the hub height of the prototype tower designed by NBTECH will be 160m in total. It is made up of two segments: an 86m high frame structure of three columns designed and patented by NBTECH; and a 71m high conventional tower placed on top.

A solution to the new challenges in the wind energy sector: the logistics and installation of XXL onshore wind turbines

The main innovative feature of the Nabralift (commercial name for the structure designed by NBTECH) lies in its patented assembly system, a new self-erecting process using hydraulic jacks on the ground. This allows for the tower to be elevated by introducing new modules from below. The tower is composed of smaller elements, which eliminates the need for specialized trucks and cranes. This new system signifies huge advances for the logistics of transport and assembly of the tower.

This isn’t the only innovation patented by this company; they have also developed technical solutions for wind turbine blades under the name of Nabrajoint. “Basically, it consists of a novel joint for a modular blade that will facilitate the transport of large wind turbine blades in two or more sections.” Says Javier Callén, Head of the NBTECH Modular Blade Program.

MAKE Consulting (a world leading consultancy firm in the wind energy sector) has identified Nabralift and Nabrajoint as two of the technological solutions capable “to address 2 of largest wind turbine technology scaling issues.”

Significant cost reduction

The Nabralift technology solution offers a significant cost saving compared to conventional towers of up to 15-20% (depending on the height and power output of the wind turbine): firstly, due to the simplicity of transport and logistics as there is no need for specialised lorries or cranes; secondly, due to its construction being 20% lighter than a conventional tower of the same height; lastly, because it is installed on a foundation of three concrete pads, which reduces the consumption of concrete by 30-40% compared to current towers.

Straightforward industrial deployment using proven manufacturing technologies

The wind energy sector is fully globalized, and all markets increasingly demand the latest generation of wind turbines. “Only a few years ago, taller towers were almost exclusively installed in Northern Europe. However, the emergence of the 3MW+ wind turbines and the saturation of areas of high wind in many countries means that markets such as Spain, India, Latin America and China are well positioned for our tower technology.”, says Eneko Sanz, General Manager of NBTECH.

To meet this demand, NBTECH has designed each part of the tower using conventional manufacturing technologies, straightforward to deploy in any continent, with maximum reliability and low costs.

In the last months, NBTECH has closed various agreements to manufacture its tower and blade components to be supplied within Europe, with the objective to deliver the first pre-series in 2019. Deployment in APAC and LATAM is expected soon due to the high level of interest shown by potential clients.

Filed Under: Construction, Towers