Marty McKewon / Indji Systems / www.indji.com

Growth in the wind energy industry remains strong with over 105 active construction projects ongoing according to AWEA CEO Tom Kiernan at a recent briefing for Wall Street investors. As the number of wind farms continues to multiply and the size of the blade and height of the turbine increases, the likelihood of lightning striking a turbine also increases. Therefore early detection of a lighting strike becomes more crucial to reducing overall repair and operating costs.

As wind farms have grown in size over the years – some now consisting of over 200 turbines – the job of identifying which turbines could have been struck by lightning after a vigorous storm can be daunting to say the least. An active storm can produce thousands of lightning strikes across a wind farm and the surrounding area with the potential for many turbines to be impacted. Early identification of lightning strikes can keep repair costs below $10,000 as opposed to more than $100,000 for full blade repair.

Technology advancements have continued in recent years to aid the various groups with a vested interest in knowing if a turbine blade was damaged by lightning. Owner-operators, the OEM, and even the O&M provider can all benefit from early detection of potential blade damage from lightning strikes. Companies such as Indji Systems are developing tools which help clients efficiently identify which turbines were likely struck and therefore where to target inspections within 24 hours of the event.

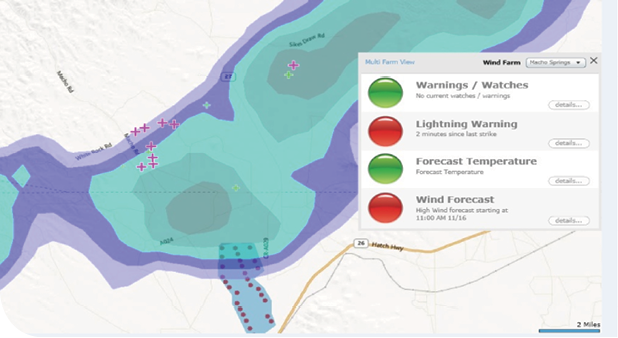

Indji Watch tracks a thunderstorm with lightning (strikes in pink crosses) as it nears a wind farm and turbines (red dots). The Indji Watch dashboard shows a Lightning Warning is in effect indicated by the red icon.

Has lightning hit my turbine?

To aid in this increasingly challenging issue, technology such as Indji System’s Indji Watch lets a site manager quickly identify which turbines may have been struck. Vaisala, an Indji Systems business partner and the provider of the National Lightning Detection Network reports that wind farm operators find 25 to 30% more damaged blades when using historical lightning data instead of just doing blanket ground searches. To address the uncertainty issue, Indji Watch displays all wind turbines in the client’s farm and lets the user interrogate recent storm data to determine which turbines were likely struck. Site managers can use this information to target an inspection to specific turbines instead of sending a crew of technicians driving around to inspect many machines. The more efficient method helps identify damage before it gets worse.

Developing confidence in the data

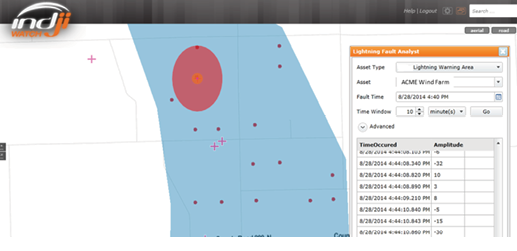

Indji Watch pin-points what appears to be a direct lightning hit to a wind turbine allowing O&M personnel to react quickly and keep owners informed of the damage. Additionally the Lightning Fault analyst also provides the time, date and amplitude (a measure of electrical current) of the strike.

While it may appear straight forward to plot a lightning strike on a map and assume that it struck a nearby object such as a wind turbine, the reality is more complicated. For example, Vaisala estimates their average location accuracy to range from near 250 meters in the center of the United States to near 400 meters on either coast. Furthermore, the location accuracy varies for each individual strike based on the number of sensors that detected the electromagnetic signal. To help the Site Manager gain confidence in the likelihood of lightning striking a turbine, Indji Watch uses confidence ellipse data. The colored ellipses represent the area in which the lightning most likely struck the ground or a turbine. Indji Watch uses the ellipses to determine which turbines may have been struck.

When a site manager sees an error ellipse representing a small area overlapping a turbine location they can have high confidence a turbine has been struck and therefore approve an inspection. However, the confidence ellipse data can also indicate if a strike was weaker and not detected by all sensors. In a scenario like this, the site manager may pass on an inspection and observe the turbine to ensure normal operation is occurring before authorizing an inspection.

Targeted inspections cut costs

The ability to detect damage early through targeted inspections can save owner operators hundreds of thousands per year. Additionally, the reports and images generated by services such as that provided by Indji Systems, offer simple documentation of events useful for insurance and end of warranty issues arising from storm damage.

Filed Under: Featured, News