Editor’s note: This article is the introduction to a technical white paper that describes the power storage device modestly named the Ultrabattery.

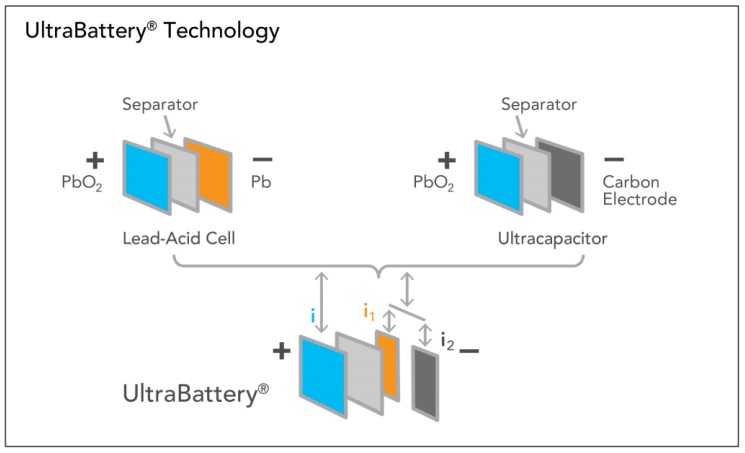

The UltraBattery, a hybrid energy-storage device, combines a supercapacitor (alternatively called an ultracapacitor) and a lead-acid battery in single-unit cells, incorporating the best of both technologies, a design that passively balances their chemical and electrical characteristics, that is, without need for extra electronic controls. The hybridization of the two technologies enhances the power and lifespan of the battery compared to standard lead-acid batteries.

The res

The schematics are for a standard lead-acid cell (top left), a supercapacitor (top right) and their combination into the UltraBattery cell (bottom).

ult is an multipurpose device, well suited to providing continuous variability management for the grid by operating in a partial state of charge that is also able to provide and absorb charge rapidly during acceleration and braking of a hybrid electric vehicle.

The White Paper has been prepared with a view to increasing awareness and understanding of the potential of this technology by summarizing and linking sources of publicly available UltraBattery test information. The data can be easily accessed and considered against the key benefits of the technology and against the market segments in which these benefits are important.

The technical breakthrough

The fundamental innovation of UltraBattery technology, developed by Australia’s Commonwealth Scientific and Industrial Research Organisation (CSIRO), is the introduction of an asymmetric supercapacitor inside a lead-acid battery (both storage methods using a common electrolyte) in a manner that modifies the behavior of the lead-acid battery chemistry to enhance power management and reduce negative plate sulfation.

The reduction of the rate of negative plate sulfation, which is the dominant cause of aging of valve-regulated lead-acid (VRLA) batteries when used in high-rate partial state of charge (pSoC), is achieved in the battery cells as an outcome of the carbon-based supercapacitor both being in parallel and sharing a common electrolyte with the negative electrode of the lead-acid cell.

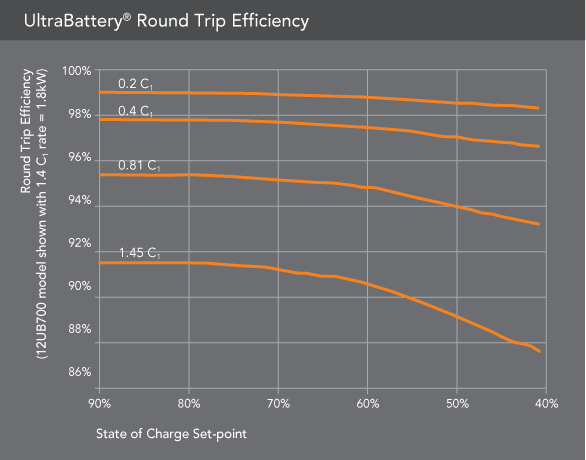

The UltraBattery is intended for high performance and low losses. An accompanying shows round-trip efficiency at a range of state of charge set-points and charge-discharge rates. Even in high power applications (1.45 times the battery’s one-hour rate) the cells average around 90% round-trip efficiency for most state of charge set-points. Efficiency soars above 95% and even above 98% as the power demand is relaxed for different applications.

The battery operates across high and low power applications, working continuously in a partial state of charge with exceptional charge acceptance and discharge capability.

Hence, whether solar smoothing and shifting, powering hybrid-electric vehicles, or smoothing megawatt swings on the grid, UltraBattery performs effectively and efficiently. So next time the choice is between power and efficiency, choose both.

Read the rest of the technical white paper here:

http://www.ecoult.com/blog/2014/01/10/new-ultrabattery-research-and-testing-white-paper/

Filed Under: Energy storage, News