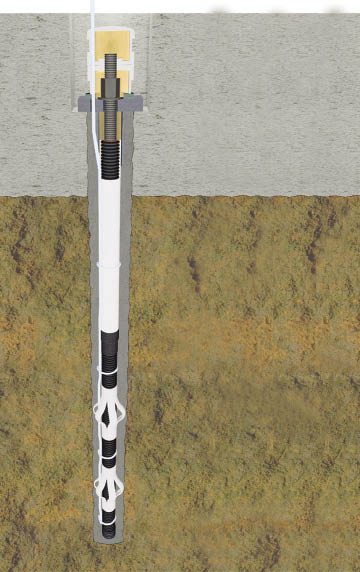

The enhanced corrosion-protected anchor is one version of large diameter rock or soil anchors installed around the perimeter of a turbine foundation. The anchors require less excavation and a substantial reduction in the amount of poured concrete versus traditional reinforced concrete in spread footing foundations. Williams has designed other rock and soil anchors in various size and strengths such as 150-ksi grade bars or 270 ksi multi-stranded tendons.

All successful wind projects begin with strong foundations. Larger wind turbines naturally call for taller towers and larger foundations that consume enormous amounts of concrete and rebar. To handle variations in wind turbines, the current state of practice includes spread-footing foundations, “tensionless” pier foundations, and hybrid foundations that use rock anchors and micropiles to resist overturning turbines and compressive loads. A brief review of foundation designs shows the advantage of the hybrid foundation.

Spread-footing foundations are most common. Large gravity concrete pads, hexagonal in shape, use about 400 to 500 cubic yards of concrete and a truckload of rebar. The load transfer from the tower is accomplished with high capacity, post-tensioned threaded bars connected to an embedment plate near the foundation bottom. Bars are sleeved through the foundation to transfer loads generated by the turbine from the tower base all the way down to the embedment ring in the foundation bottom. Enginneers traditionally specify a preload for the anchor bolts that is higher than the tower service loads, thus eliminating fatigue and impact factors. Post-tension bars use clever cold-rolled “knuckle” threads, which are more durable than regular NC (National Course) threaded bars necessary for ease of tower installation.

Hybrid foundations are one way to reduce concrete and rebar, and are becoming more common. In them, a shorter (shallower) and smaller diameter concrete “cap” is constructed with blockouts – recessed holes – to allow drilling through the constructed

foundation. Contractors then drill a small, about 8-in. diameter, hole to a depth dictated by geotechnical reports (typically 30 to 40 ft), place an anchor in the hole, and completely fill it with a grout-a neat cement. Anchor features include a no-bond zone (also called a Free Stressing Zone) at the upper 10 ft of the anchor, so the load transfers deep into the ground. Good practice requires a load test on every anchor, as well as an extended “creep” test, one that evaluates the anchor movement over time, on a sampling of the production anchors. The anchors are then locked off at loads higher than anticipated service loads.

Long ground-anchor bolts, 40 ft in some cases, allow using smaller diameter and shallower foundations for wind turbines.

As turbine and tower technologies change, so must foundations. What was common 10 years ago is no longer the standard, and a decade from now the foundations on wind farms will continue to evolve to meet higher loads and stricter design standards. WPE

By: Tom Bird, Vice President, Western Division of Williams Form Engineering Corp.

Filed Under: Components, Construction

Dear WindPower,

I am a senior at Moody High School Innovation Academy for engineering, marine biology, and environmental science. This public magnet high school located in Corpus Christi, Texas, focuses on preparing students like myself to excel in STEM (Science, Technology, Engineering, Mathematics) related careers. As part of my graduation plan, I am required to find, justify, design and test a uniquely individual research project. This project, when complete, will be presented to the faculty and peers of my school in the spring of this year. My project is entitled the “Tul-bine”, which is a combination of the words tulip and turbine. Its primary purpose is to improve wind turbines, so they do not cause destruction to the environment or to people’s health. Another renewable resource I plan to use is solar energy to produce additional power. For my project, I am going to create a portable wind turbine that has the appearance of a tulip, with leaves as solar panels for additional power being generated.

The purpose of this letter is to request support for my project prototype design. I found in your web page that you sell the ground anchors for small wind turbines, which would be perfect for my project, because I have been searching for different methods of grounding my turbine. Would there be a way for you to help sponsor me with this product? Being a high school senior, I am unable to buy this product myself. I will be able to give your company recognition in my multimedia presentation and record your help in my final documentation.

If you are able to help me with my project, I can be contacted at the address found on this letterhead. My email address is destinysol94@gmail.com. Writing or calling my Engineering Design & Development instructor, Ms. Mari Rivera-Roman may confirm my project and materials needed. Her email address is mari.rivera-roman@ccisd.us. Should you not be able to help with these tools, may you recommend another source of supplier that might be available?

Any and all help for my project would be greatly appreciated.

Sincerely,

Destiny Soliz

Destiny,

Please email me directly at nsharpley@wtwhmedia.com.

Thanks,

Nic