Wind turbine technicians at Rope Partners apply a 3M Wind Protection Tape to a blade’s lead edge. Photo: Rope Partners

Those wind turbines on the distant hillside may seem like they are turning at a lazy 15 rpm, but in fact, their blade tip speeds could be exceeding 160 mph. Some blade tip speed can reach up to 250 mph. Being exposed to the elements — rain, hail, and salt spray – can wreak havoc on blades traveling at such high speeds and lead to erosion of the leading edge. Over time, blades suffer pitting, gouging, and delamination. These issues may seem minor, but over time can compromise a blade’s aerodynamic performance, reduce a turbine’s annual energy production (AEP) up to 20%, and eventually cause costly downtime. To protect the blade, 3M (www.3m.com/wind) has developed a tape and coating that helps prevent leading edge erosion. The company says coupling these blade repair materials with protection practices increase AEP, while reducing downtime and costs.

Wind protection tapes

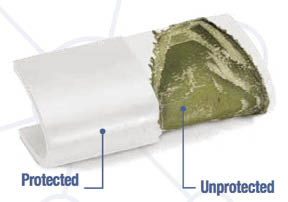

3M says its Wind Protection Tapes are intended to resist erosion, puncture, tearing, and weathering and are adapted from the technology developed to protect helicopter blades and aircraft radomes. The tapes are constructed from tough, abrasion-resistant polyurethane elastomers, which shield leading edges and surfaces from pitting, wear, and water ingression.

The Univeristy of Dayton’s Research Institute tested 3M’s Wind Protection Tape in a rainfall simulation of one inch per hour at 500 mph.

“The tapes conform to complex shapes and are UV stable and solvent-free,” says Christian Claus, global business manager, 3M Renewable Energy. “They require no special application tools and are easily applied either in the factory or in the field by rope or platform access. When applied to the leading edge of a wind turbine blade, the tapes help maintain turbine efficiency, by reducing downtime and maintenance. What’s more, the tapes also extend the useful life of a blade, even in the harshest environments,” adds Claus.

Wind blade protection coating

3M says its Wind Blade Protection Coating helps protect the leading edge of a wind turbine blade from minor damage, such as sand and rain erosion. The two-component polyurethane coating provides erosion protection in a single layer, and can be applied using a brush. Its fast curing means it can be applied in the factory, helping manufacturers produce blades that are protected against erosion from the first day of service.

Filed Under: Featured

All due respect to 3M but you have yet to come up with any coatings or poly tapes that have out performed nickel abrasion strips. I have been in the rotor blade repair business for 39 years and tried them all. You do however make a good film adhesive (AF 163-2K) yet expensive that we use to bond our abrasion strips.

I think these tapes are really supportive. These tapes protects from corrosion, scratches and other damages. It adds life to the materials by preventing it from ageing. Surface protection worth’s, it really protects your investment.

Hello, I think that is a remarkable step,that helps in adding more lifetime to the turbine blades.

Good luck