Romo Wind and eta Blades are cooperating to provide customers with solutions to improve the performance and extend the lifecycle of the growing number of aging wind farms.

Romo Wind’s iSpin technology monitors the performance and the wind site conditions for detailed load and lifetime assessments. eTa Blades re-designs and manufactures lighter and aerodynamically efficient blades for older turbine types. Together, the two companies are joining forces to provide an attractive refurbishment package for aging wind farms.

“Based on eTa Blades deep understanding of airfoils and wind-turbine loads, ROMO Wind will further step into helping customers improve asset performances and extend the lifetime of their aging wind assets with outstanding re-blading solutions,” explained Brian Sørensen, CEO of Romo Wind.

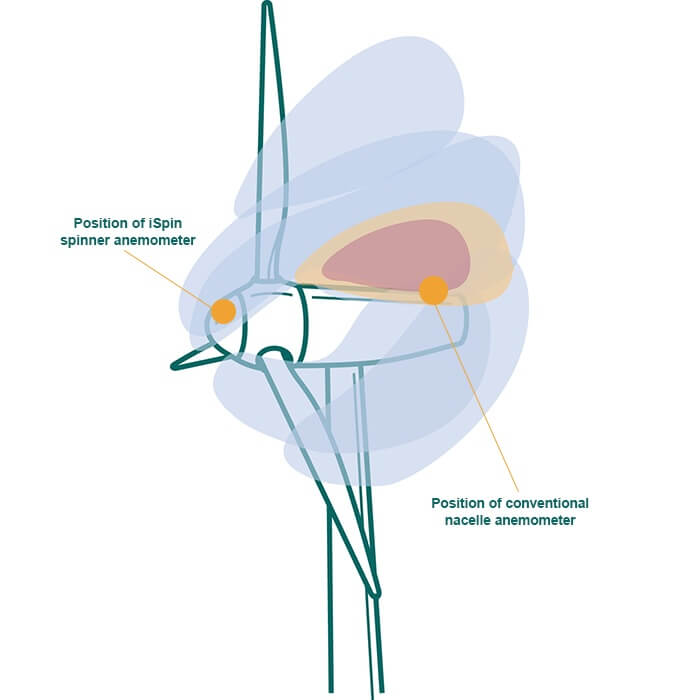

The ROMO Wind iSpin system uses proven ultrasonic technology to measure wind where it first hits the wind turbine – directly at the spinner. In this way, operators gather accurate information on the wind conditions in front of the rotor. This enables them to check whether their turbines are aligned for the best possible yield.

According to Romo Wind, measurements show that more than half of all wind turbines equipped with iSpin have significant yaw misalignment. The company says that on average, wind owners can expect a 2% production increase from your wind farm by applying iSpin.

“The advanced iSpin measurement technology with its unprecedented abilities to monitor wind speed, direction, yaw misalignment and turbulence intensity, as well as the performance on each of the turbines in a wind farm, helps us to optimize turbine operations for our re-blading projects to maximize power output while still keeping within design limits,” said Carlo Durante, founder of eTa Blades.

Filed Under: Blades, News, O&M