Drone company, SkySpecs, announced that it has completed a record number of automated wind-turbine inspections in a 30-day period. The company provides fully automated blade inspections using a drone and intuitive software that allows for high-quality data and safer inspections.

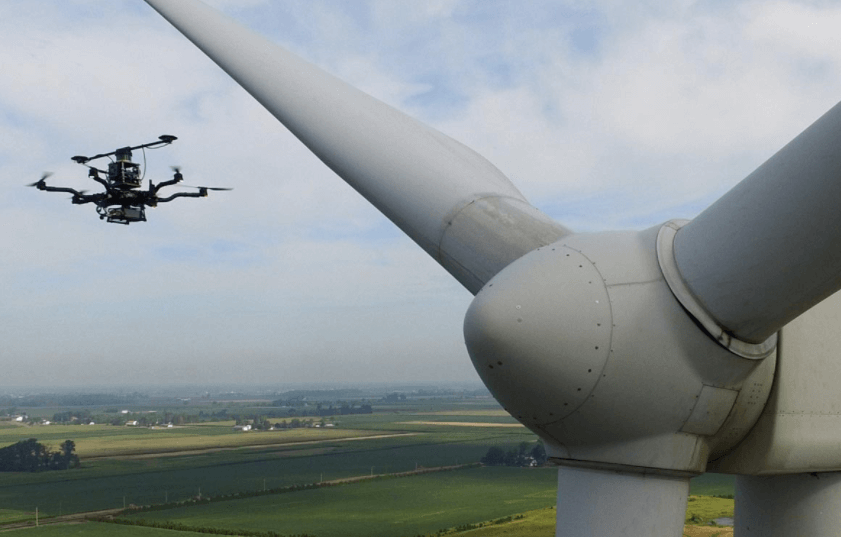

SkySpecs’ autonomous drone inspections are making 15-minute wind-turbine blade inspections possible in many cases. (Photo: SkySpecs)

“It has been an exciting few months at SkySpecs with operations in multiple states and countries,” maintained Danny Ellis, CEO & Co-Founder, SkySpecs. “In the last month, we have completed a record number of wind-turbine inspections in a 30-day period, totaling 483 turbines or 1,449 individual blades, with an average of two operational systems at any given time.”

According to SkySpecs, no other inspection method or manually flown drone operation has been able to achieve this level of speed and repeatability in wind-turbine blade inspections. The drone inspections let customers identify problem areas faster, and optimize repair schedules and costs earlier and more accurately.

SkySpecs is collaborating with iSight RPV Services to fulfill inspection contracts in the U.S. iSight RPV Services provides remotely piloted vehicle operations to critical infrastructure and other industry, so as to better unlock the value of collecting information with unmanned aircraft.

“Using the SkySpecs system in the field has completely changed the way I work,” explained Adam Overvold, iSight RPV Services operator. “I press GO to launch the inspection and the whole thing is finished in under 15 minutes. The time between turbines using SkySpecs’ system is 23 minutes as opposed to manual inspections, which were two hours from turbine to turbine.”

iSight RPV has been able to deploy highly qualified field operators who are able to complete the inspections using a single-man team. The autonomous drone inspection system allows the field operator to complete the fastest, safest, and most precise job possible with little disruption.Turbine downtime is minimized, and the overall energy-loss impact that inspections typically bring is greatly reduced.

The speed of the inspection also allows for an entire field to be inspected in a matter of days or weeks instead of months. The measurable, repeatable data improves the ability to predict problems in the field and deploy repair crews before the problems escalate. This, in turn, leads to higher efficiency in the energy generation and lower overall operations and maintenance costs over the life of the turbine.

SkySpecs is on track to continue increasing the number of inspections completed per month.

Filed Under: Blades, News, O&M