Staffan Engström/Consultant Agir Konsult AB/Nordic Windpower/ Taby, Sweden

A dampened pivot hub, modular drive train, and regulated tip speeds give two-bladed, utility-scale wind turbines a few advantages over three-blade designs.

Nordic Windpower focuses on developing the advantages of two-blade turbines. The company manufactures a 1 MW unit with larger rating in the works. The firm’s earliest units are now 10 years old and have recorded an availability of about 98%.

For a wind turbine to output a particular power, it must have a certain rotor diameter, rotational speed, and a specific aerodynamic area. Although most modern wind turbines use three blades, distributing the necessary surface area over just two turbine blades provides several advantages.

The pros of two

The primary effect is that blade chord (leading edge to trailing edge) must increase. Because a blade profile is characterized by its relative thickness (blade thickness to blade width provides a ratio, normally of 0.15 to 0.20), this also means the blade thickness increases with increased chord. One consequence of a thicker blade is a considerable increase in strength. For a beam, strength is proportional to the third power of its height, or

S ∝ h³

where:

S = strength of the beam and h = airfoil height or thickness.

A thicker blade decreases the need for structural material, which makes the blade lighter and less costly. Because this is in addition to the fewer number of blades needed, the total blade cost drops significantly.

Another significant advantage is that it is easier to erect a two-bladed wind turbine because the blades may be mounted to the nacelle while it is on the ground. A three-bladed rotor must be lifted separately and mounted to the nacelle when it is on the tower. The separate lift is an additional cost.

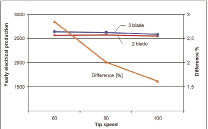

Under the same general wind conditions, the two-bladed turbine is slightly less efficient than the three-bladed. The difference in the yearly energy production would be about 2 to 3%, but this is easily compensated for with a 1% increase in rotor diameter. Thus, this is no argument against the use of two-bladed turbines.

Nordic Windpower recently shipped the first of 16, 1-MW turbines from its new factory in Pocatello, Idaho. A safety cage surrounds the likely work area on the hub. The oval hatch provides access to pitch mechanisms. The round feature to the right of the hatch is the pivot bearing that allows the rotor about ±2° of movement. The four black discs are cushions or dampers that dissipate pivoting energy.

The reason for the current dominance of the three-bladed turbines is that a two-blade turbine was harder to develop. This is a consequence of its asymmetry, whereas the three-bladed turbine is symmetrical.

Due to complex calculations, access to a comprehensive and easy to use computer simulation is a necessary prerequisite to exploite the advantages of two-blade technology. Nordic Windpower now operates such a program. It was developed in the Swedish wind energy research program in the early l980’s.

Another prerequisite for a successful two-bladed wind turbine is a tilting or teeter hub, which means the hub and blades are hinged to the turbine shaft. Although the pivot range is quite small (± 2°), this motion has a decisive influence on the loads acting on the entire wind turbine.

The lack of accurate computer simulations slowed development of two-blade designs. In many cases this resulted in technical problems and is why most OEMs implemented the less demanding three bladed design. However, the technical advantages for two-bladed wind turbines have long been known to the wind power community, and are why the Swedish National Wind Power Program concentrated its efforts on two-blade technology in the 1970s. For instance, the Swedish program found that the design features needed for a successful two-blade implementation include:

•A pivot hub with damping to dissipates blade forces before they reach the gearbox.

•An integrated drive shaft and gearbox that allows for a more durable bearing configuration

•A single unified, tubular housing for the gearbox, drive shaft, and generator to hold this equipment steady and let forces dissipate away from the gearbox

•Cooling of the gearbox and generator to keep oil temperatures well below critical.

Other advantages

When these features are combined in a single design, two-blade turbines show several advantages over three-blade units. For example, onshore wind turbines are usually limited in their power production by their noise output which is determined by the blade-tip speed and hence rotational speed. Siting wind turbines offshore avoids this problem. Two-bladed turbines benefit more from this location change than three-bladed turbines. The 50% larger chord and greater structural blade strength allows increasing tip speed to substantially larger values than those that are possible with three-bladed turbines. This is of great importance, because the cost of the gear box or direct-drive generator is inversely proportional to the rotational speed, or:

C–gearbox ∝ 1/ω-rotor

where:

C–gearbox = cost of the gearbox, and ω-rotor = rotor speed.

This leads to further cost reductions. The need for large turbines and the easier handling of two-bladed designs are more reasons these turbines are likely to find wider use offshore than on.

Equal noise or less

Noise restrictions determine an acceptable blade tip speed for onshore wind turbines in populated areas. Two-blade wind turbines are designed for the same tip speeds as three-blade designs. Fewer blades have fewer noise producing surfaces. This will even result in slightly less noise, about 1 dB lower than corresponding three-bladed turbines.

Shadows

Flicker or shadows from a turbine blade hitting a building’s window results in an annoying variation of lighting conditions inside the room. An investigation by the Swedish government (Vindkraftsutredningen, SOU 1999:75, p. 101) concluded that an annual cumulative shadow time of 10 hours is acceptable to inhabitants. This factor may become increasingly important because the generally less noisy wind turbines are placed closer to buildings which will make shadow conditions important in determining acceptable distances to nearby habitation. A two-bladed turbine has a shadow frequency of 2/3 that of a corresponding three-bladed turbine.

A thicker cross section provides a stronger blade and hence, fewer blade problems on two-blade turbines.

Improved visual appearance

This topic is, of course, quite subjective. The experience of the general public with two-bladed wind turbines is mostly with small units. These have a high rotational speed, regardless of their blade number because any wind turbine is designed for a certain blade-tip speed, which makes the rotational speed inversely proportional to the turbine diameter. The high rotational speed on a small two-bladed turbine has the drawback of making the rotation appear irregular, which disturbs some people. However, the impression disappears by increasing turbine size and decreasing rotational speed.

The visual experience of rotational-speed differences is primarily connected to the frequency of blades passing the tower or horizon. At the same rotational speed, the blade passage frequency of a two-bladed turbine is just 2/3 of the value of a three-bladed turbine. This may be why large, two-blade turbines, some say, appear calmer. WPE

Filed Under: Community wind, Featured