As wind and solar compete as serious contenders in generating more energy, energy produced must be as cheap, if not cheaper, than that of fossil-based sources, and the quality of energy equally as high, says The Switch in recent news.

The company says the formula for lowering the cost of solar and wind energy from any source is ultimately simple: Lower overall capital investment costs, equipment lifetime operation and maintenance (O&M) costs and fuel costs while boosting the amount of energy generated. This formula becomes even more attractive with wind and solar – as the cost of fuel is already free!

The Switch has taken a closer look at 4 ways to lower the costs of energy that affect the remaining variables:

1. Raise annual energy production

High availability and efficiency curves make for a winning combination to boost annual energy production (AEP).

Availability

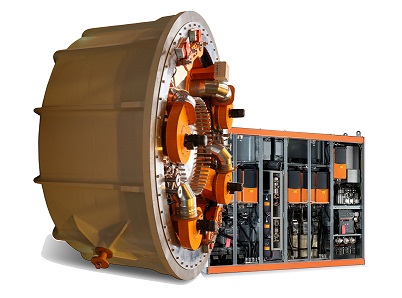

The simplest way to increase AEP is to keep turbines or solar plants up and running. Though the wind and sun may come and go, the equipment must continue to operate and produce a constant stream of high quality energy. Technology such as PMG (permanent magnet generation) can help reduce failures. Minimizing the downtime of the equipment and scheduling regular maintenance and tune-ups for low wind or solar periods also helps keep equipment operating at its highest availability.

Efficiency

When it comes to efficiency curves, PMGs also excel. Operating at peak efficiency or power does not account for better AEP rates. Rather, improved AEP comes from the amount of time a wind turbine spends generating electricity over all wind speeds. PMGs demonstrate higher efficiency at partial loads where they spend the greatest number of their operating hours, resulting in a proven higher efficiency curve. Moreover, PMGs start producing power at lower wind speeds, enabling them to add more power to AEP rates.

2. Minimize total life cycle costs

Cutting back on total life cycle costs (TLC) means scrutinizing the expenses associated with both the initial capital investment as well as the O&M costs over the lifetime of the equipment. These two essential expenses must be optimized to bring about the best long-term results.

Capital investment

Going for a low-cost initial equipment investment may not always be the wisest. In fact, it may even lead to higher hidden expenses when it comes to O&M costs throughout the equipment’s lifetime of 20 years or more. Technology such as a double-fed induction generator (DFIG) can help cost about 30% of initial investment costs because it uses a partial converter rather than a full-power converter. However, it is important to factor in all additional costs of getting the DFIG connected to the grid according to the latest international grid code requirements, as this may entail much more costly connectivity solutions and lost production time.

Operation and maintenance

When maintenance is scheduled for low seasons in wind and solar, it is cheaper and faster. Moreover, when a recommended maintenance program is followed, it is possible to minimize breakdowns and ensure smooth operation.When comparing the maintenance costs of a PMG turbine with a DFIG turbine, the potential savings are considerable. The estimated maintenance time between failures (MTBF) for a PMG and full-power converter is 8,000 hours compared to only 1,500 hours for a DFIG.

3. Extend the lifetime of equipment

Typical renewable energy generating units, like wind turbines or solar panels, have an estimated operating lifetime of 20 years with today’s technology. By lengthening this time with an additional three to five years, the cost of energy can be lowered dramatically.A good purpose-built design, well-selected materials and components, and a carefully planned maintenance program can lengthen the lifetime of the equipment substantially. For example, a well-designed drive train minimizes cogging torque, reducing the amount of vibration and lengthening the lifetime of all components. Another way to extend the lifetime of equipment and increase its production efficiency is through upgrades, retrofitting and recycling of components.

4. Boost the quality of electricity

In the end, the success of renewable energy depends on the quality of electricity it feeds into the grid. News from recent incidents of wind turbines not connected to the grid has overshadowed some of the earlier favorable progress. Now the industry and governments alike are responding – with stricter and more uniform grid code regulations.

The Switch

www.theswitch.com

Filed Under: Generators, News, Turbines

Turbine capital costs are the largest factor in wind LCOE. Switching to DD or medium speed PM generators will only increase capital costs. PM generators do have slightly better efficiency than conventional synchronous designs, but you also need to consider the losses in the power electronics. As for O&M costs, power electronics are now the largest source of failures and downtime. A DD PM generator that requires full power conversion will not improve this situation.