Industrial artificial intelligence (AI) leader, Uptake, announced it is providing comprehensive data integrity O&M capabilities, allowing work order cost analysis that overcomes the challenges with incorrect or “dirty work order” data. According to Uptake, dirty data means it is out of order, highly volatile, and has a lot of room for error.

Uptake says its APM capability for data integrity is a first for the industry, allowing companies to successfully implement predictive maintenance strategies that increase revenues and reduce annual O&M costs by up to 20%.

Companies worldwide are using advanced analytics and machine learning for predictive maintenance strategy optimization as a driving force to reduce operational costs. However, the lack of clean data is a major impediment to achieve those cost savings, says Uptake.

Industrial companies are particularly susceptible to dirty data due to wildly disparate, legacy systems, frequently missing, or miswritten, data, and the prevalence of proprietary systems that have their own data language.

Uptake believes it has solved this problem. “Operational and maintenance data in the industrial, energy, and utilities sector is often inaccurate or missing critical pieces and AI-driven insights are only as good as your data,” said Jay Allardyce, Uptake’s Chief Product Officer. “This Uptake APM capability for data integrity is a first for the industry allowing companies to successfully implement predictive maintenance strategies that increase revenues with better insights and reduce annual O&M costs by up to 20 percent.”

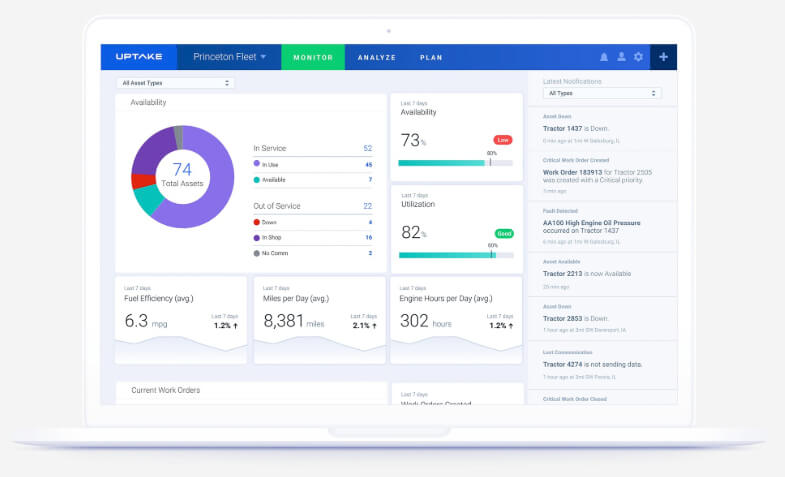

Asset IO, Uptake’s Asset Performance Management (APM) application, includes a new module capability to ingest years of work order data, which comes from existing computerized maintenance management systems (CMMS) and enterprise asset management (EAM) systems. Asset IO leverages artificial intelligence and natural language processing to complete missing data, suggest asset labels, and create an asset category schema where none exists.

The result is a clean dataset for work order cost analysis that can be used to inform critical preventive and predictive maintenance strategies to de-risk operations and reduce annual O&M costs significantly.

“There is a major barrier for industrial plants when it comes to leveraging the value of their assets using current EAM/CMMS software,” said Mike Guilfoyle, Director of Research at ARC Advisory. “These systems are not designed to deal with many of the data challenges common in work orders, such as incorrect or incomplete information, role and location-based variations in word meaning, and the heavy use of slang and shorthand, which can change over time.”

Guilfoyle added: “So much organizational knowledge is locked within these work orders, unable to be leveraged as the key intellectual property it is. By overcoming this barrier, industrial plants can use this knowledge to reduce their O&M expenditures without raising production risk and better execute maintenance strategies aligned with operational excellence goals.”

The Uptake Asset IO application also leverages Uptake’s Asset Strategy Library, which has records of over 58,000 machine failures and over 800 critical asset types and has been trained on over 2.1 billion hours of operational machine data that allows customers to leverage the largest library of asset types, machine failures and preventive maintenance strategies data in the world.

By deploying Asset IO, industries can unlock new operational efficiencies by making proactive maintenance decisions based on predictive insights. Our industrial AI and machine learning engines understand over 10 million different components to help predict and prevent problems before they happen.

Filed Under: News, O&M, Software