The global wind-turbine blade market is also expected to grow and garner a lucrative 8.6% CAGR (compound annual growth rate) from 2019 to 2027, according to a report by the Market Research Future, a business analyst firm.

Supersized. That’s an ideal description of what’s expected in the future of wind-turbine blades. They’re going to get big. What once extended the length of a basketball court will soon span the length of two (or more) American football fields. At least that’s what General Electric (GE) has been working on for wind.

“It would take two minutes for the average person to walk from the tip of one turbine blade to the other,” states a GE Report about the company’s 4.8-158 wind turbine. Initially announced in 2017, the onshore turbine is aptly named because it generates 4.8 MW and has a 158-meter rotor and 77-m blades.

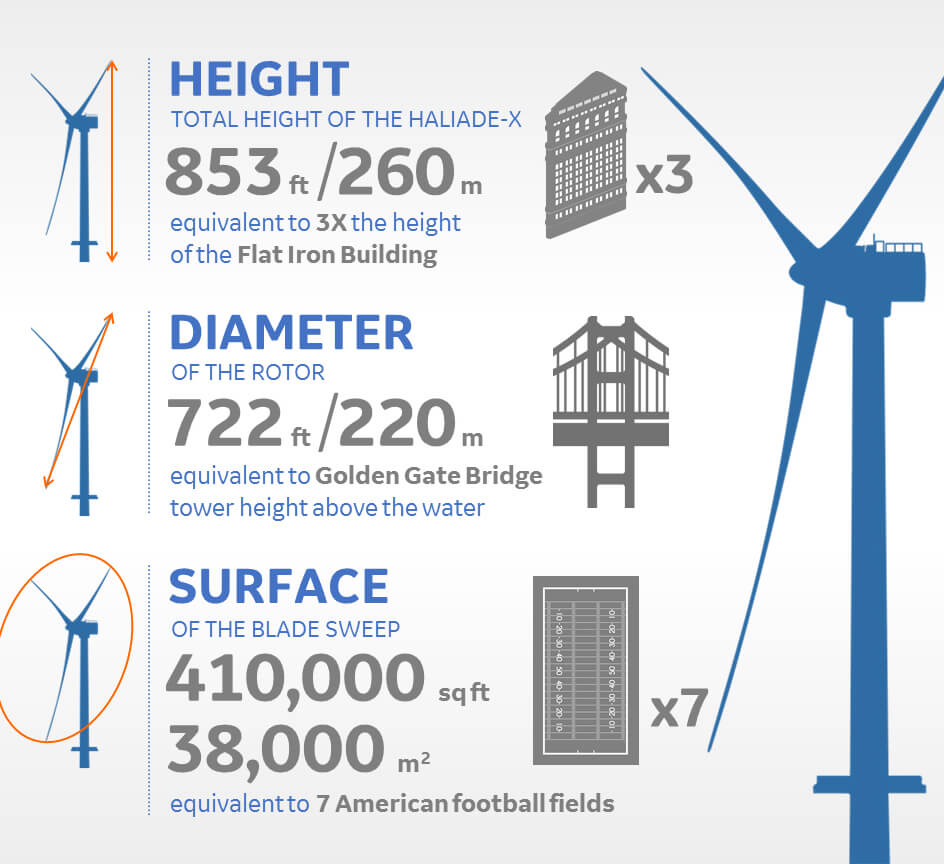

GE is also working on Haliade-X and what’s been called, “the most powerful offshore wind turbine in the world to date.” With a massive 12-MW capacity — a world-first — the Haliade-X is expected to have a 220-m rotor diameter and 107-m blades, designed by LM Wind Power. That’s a blade swept area of seven football fields. LM first set the record for the world’s longest blade a few of years ago, which measured in at 88.4 m with a 180-m rotor diameter for manufacturer Adwen’s 8-MW offshore turbine model.

Note the trend: blades are getting bigger on and offshore. The reason? Bigger, more powerful turbines that can generate more energy require longer, more powerful blades. Taller towers typically reach stronger winds and longer blades cover a greater swept area to better maximize production. Higher capacity turbines also mean a wind project requires fewer turbines to produce power, cutting construction and O&M costs.

Wind already offers one of the lowest costs of energy in the U.S. In fact, the national average is down to $20 per megawatt-hour, according to a 2018 report from the Department of Energy’s Office of Energy Efficiency & Renewable Energy. That cost may drop further, thanks to bigger turbines with longer blades, and particularly as the offshore market develops in the U.S. A greater ROI at lower operating costs is a business win-win.

However, this is easier said than done. Larger machines are typically heavier and more challenging to engineer. According to GE, while turbine blades have conventionally been made from fiberglass, the new ones are made with carbon to cut down on weight.

Learn more about GE’s Haliade-X here.

DNV GL, the world’s largest regulatory body, has also researched the effects of larger wind-turbine blades. In addition to manufacturing challenges, the organization points to logistical constraints that may reduce the number of developable sites because of the cost to transport the blades to such remote locations.

DNV GL released an in-depth study earlier this month, commissioned by the U.S. Department of Energy’s Lawrence Berkeley National Laboratory, which examines the challenges associated with manufacturing and deploying larger onshore wind turbines. The organization examined three “pathways to help identify high-value R&D opportunities” for supersized blades, including: innovative transportation, modular or segmented blades (for less costly transportation), and onsite manufacturing.

The goal of the study is to enable wide-scale deployment of supersized turbines and turbine blades across all regions of the United States.

An additional factor to consider relating to larger turbine blades is maintenance. Wind operators already rely on sensors and condition-monitoring systems to detect component abnormalities or faults and drones have taken over many blade inspections, detecting damage or leading-edge erosion.

New research is focusing on data-driven artificial intelligence (AI) to help manufacturers select the ideal blade material from the outset. The erosion of materials used in blades is a costly effect of the harsh climate wind turbines are typically exposed to. This is particularly true of offshore turbines. However, with AI, it is possible to quickly and effectively analyze an unlimited number of different material compositions used in blades to find the most reliable one for a given project’s climate.

“Human perceptive skills are insufficient to visualize all the dimensions related to the optimization of material solutions,” said Anssi Laukkanen in a recent press statement about the research. Laukkanen is the principal scientist working on what’s called the antiAGE project at the VTT Technical Research Centre in Finland. “AI, on the other hand, is capable of unraveling very complicated cause-and-effect relationships, simulating solutions, and going through an infinite number of alternatives to find the one that works best in relation to the requirements set.”

This may mean it’s possible for blades to be composed of the same material components with slightly varying properties, depending on the turbine or project. What’s more: 3D printing or additive manufacturing is being considered to produce cost-effective materials in any shape.

Another research team working on the Leading Edge for Turbines (LEFT) project in the UK is using aerospace technology to develop a unique leading-edge protection system for offshore wind turbines. The system would virtually eliminate the need for O&M intervention related to rain erosion and allow for lighter wind-turbine blades and drivetrains.

According to the LEFT researchers, rain erosion is currently the leading cause of damage to turbine blades and is a particular problem for turbines with longer blades and greater tip rotation speeds.

Although longer turbine blades are likely to generate greater wind-power production, bigger blades and turbines will come with new challenges to address — something wind researchers are clearly already working on.

Filed Under: Blades, News

Heard in the Sierra Club magazine that:

“Painting one of a wind turbine’s three blades black can reduce bird strikes by over 70 percent. “

Is there a way to add this aspect to the improvements in wind blade designs?

I like this. My problem is the way the blades are disposed of. Barring any defects, why are the blades stood up and mounted to a flat disc and still used to make power? I am not a college educated person just a curious consumer.