The challenge to the nascent U.S. offshore wind industry is to learn from the experiences of European offshore wind, U.S. offshore oil and gas, and onshore wind, and then come up with a reasonable set of best practices and standards. This will lead the industry toward an initial safety position that is proactive and near ideal. Doing so will avoid the scenario in which after someone is seriously hurt and every agency that can, reacts by applying too many rules. That was the message from Ron Beck at the recent AWEA Offshore Conference in Atlantic City, NJ.

Beck had more to say about safety along with the three other panelists who have formed Ocean Readiness, a partnership that aims to develop onshore health and safety (Tanjia Maynard), workforce development (Meagan Amsler), and offshore wind-project installation (Joel Whitman). The four partners bring a wealth of skills and experience from their primary organizations, Beck – Tetra Tech, Maynard – PMSS, Amsler – Cape and Islands Self-Reliance, and Whitman – Whitman Consulting Group.

Prescriptive health and safety regulations do not currently exist. However, the regulatory agencies identified have an EHS role defining the regulations for offshore work.

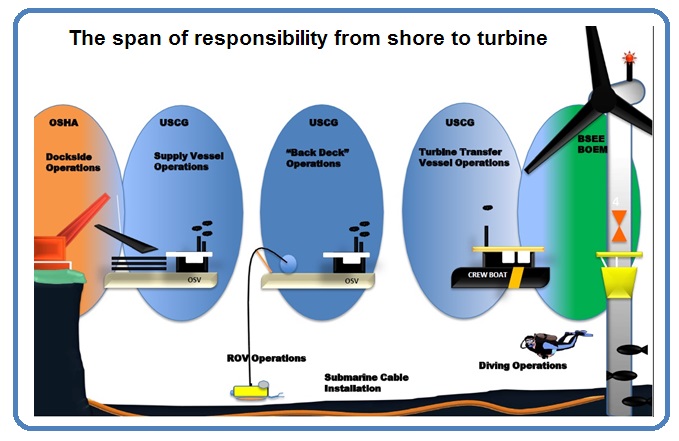

The main players in the offshore regulatory environment are OSHA, the U.S. Coast Guard, Bureau of Ocean Engineering Management (BOEM), and Bureau of Safety & Environmental Enforcement (BSEE). OSHA authority is limited to state waters. “Projects such as Block Island wind farm, Great Lakes near Cleveland, and Fisherman’s Energy in New Jersey would be examples of projects under OSHA’s jurisdiction . Proscriptive health and safety regulations are not in play right now. It takes a lot of effort to develop them. But we’ve seen in other situations that safety regulations always sort of lag behind the need for regulatory proscriptions,” says Beck.

The four agencies mentioned have different roles in different places. “For instance, if you look at OSHA back at the dock, there are quite a few regulations for shipyards and for activities on the pier. We see regulatory definition there, but then when loading an offshore supply vessel, there is a shared responsibility because that activity brings the vessel into play, and the vessel is regulated by the Coast Guard. For instance, crew transfer vessels are regulated by the Coast Guard.

Move further out to sea to the wind turbines, and BSEE and BOEM regulate health and safety responsibilities. “One of the reasons that it is so important for proactive best practice writing is that during crew transfers, regulatory jurisdiction over safety shifts during the transfer. “ says Beck.

So far there are few marine safety regulations specific to offshore wind farms in the U.S. The Coast Guard will use its authority over offshore supply-vessels for jack-up vessels, transfer vessels, and the other vessels involved with offshore work – those flying U.S. flags. For foreign-flagged vessels, the flag state, under which they are registered, has regulatory oversight under International Maritime Organization (IMO) regulations. For instance, in the U.S,. the IMO Standards for Training and Certification of Watchstanders, or STCW, only applies to vessels on international voyages and those greater than 200 tons. “But the STCW basic safety lessons are something appropriate for what’s happening in the offshore wind industry and will be addressed in a slightly different way for everyone other than the mariners on the vessels that are either greater than 200 tons or engaged in international voyages,” says Beck.

The four identified organizations will govern safety operations on a range of vessels, authority that extends from dockside to the wind turbine.

BOEM safety management regulations under 30 CFR 585.810 are less than a page long, and they basically say that the wind industry will have a safety management system and it will be self-audited. “There’s an example Safety Management System provided so you have an idea what one should look like. One important result of a National Academy of Sciences Marine Board on offshore worker health and safety was for offshore wind to move towards a safety and environmental management system (SEMS) similar to what has been required for oil and gas. That recommendation stands,” he adds.

So from what industries can the budding offshore wind industry learn? Beck says one rule that makes sense is that if you have similar turbines three miles offshore and more 20 miles out, onshore regulations, such as those for lockout, tag-out, and other OSHA rules, should not change. “I think OSHA regulations will become best practices even though OSHA enforcement offshore isn’t going to be directly applied,” he says.

He added that he is working with several people to devise a safety program. In the initial stages, lessons are not going to be proscriptive nor will they be immediately codified. “If you follow the safety and environmental management approach of zero harm, the attitude will move from a compliance culture that runs through checklists and says, ‘I’ve worked through this list, so I’ve covered myself as far as being in compliance with regulations.’ The industry will move to a safety culture in which members look at leading indicators rather than lagging indicators.”

One interesting thought from conventional wisdom is it’s all fine now because there is no offshore industry. No one has yet been hurt. “But after the first bad accident, the four agencies will likely have to provide more help than anyone would ever want,” says Beck.

So the opportunity now is to react to leading indicators such as near-miss reports, audits, and the safety training being applied. “That is preferable to examining who got killed or maimed in the offshore wind workplace. That is the challenge for us. The other part of this safety thinking is that if we can incorporate all the experience we have from Europe, U.S. offshore oil and gas, and onshore wind, and come up with something that is a reasonable set of best practices and standards. That will lead the industry towards a much safer environment that will avoid a scenario in which we have to learn through a series of bad accidents. Part of the whole process is to include a feedback loop, so if we have an incident, we must get the lessons learned back into the safe-working practices and let people know that, for example, there has been a crush injury because of a particular situation. That informs how the work is done and hopefully reduces risk in future.

“I’ll leave you with a challenge. The industry has a rare opportunity here that’s almost like a whiteboard clean of heavy regulations. If we can step up and raise the bar a little bit above the minimum and do what is going to be effective for offshore health and safety, it’s going to serve us very well in the future,” concluded Beck.

Filed Under: Construction, News, Offshore wind

There is still work to be done but I am confident with the help and commitment of my fellow G9 members and the wider offshore wind business community we can work together to make this industry a safer place to operate. As the statistics show how the current situation is.