The battle against corrosion goes on with no ending in sight, especially for coastal and offshore wind developers. Salt spray there is particularly damaging to exposed metal. However, a recent inorganic coating developed by Unitel Technologies (www.uniteltech.com) and Inorganic Polymer Solutions, Inc. (arunwagh.com) may give wind developers a promising weapon.

A closer look at the coating

The top coat is made up of refractory oxide particles bonded by the phosphate binder.

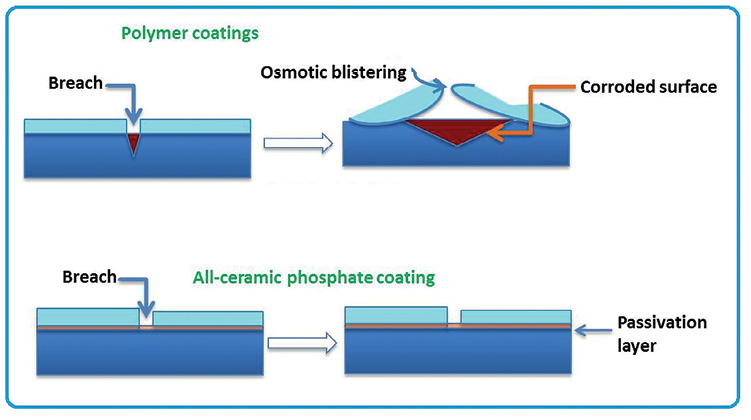

CeraStrata builds its own passivation layer that defends against osmotic blistering.

CeraStrata is a chemically bonded, all-ceramic, 100% VOC-free coating applicable to a wide range of materials, including steel, concrete, and wood. What’s more, it lasts longer and costs less than galvanizing and is not affected by high temperatures, oxygen-deficient conditions, or marine environments, says Unitel.

“Dust and debris in the wind will scour turbines and abrade their paint, and then their steel structures corrode,” says Arun Wagh of Inorganic Polymer Solutions. “We need a coating tougher than polymer paint to reduce this abrasion.”

Conventional polymer coatings can give way to a phenomenon known as osmotic blistering. This occurs when corrosion develops under the protective coating, destroying the metal surface so that the paint peels away.

“Corrosion of steel is accelerated by a saline atmosphere, and any structure, off-shore or one along the coast, needs tougher paints to reduce osmotic blistering,” says Wagh. “CeraStrata, with its passivation layer on a steel surface almost eliminates osmotic blistering.”

Osmotic blistering and a solution

Wagh initially developed Ceramicrete (phosphate cement) technology at the Argonne National Laboratory to immobilize nuclear waste. He had to ensure the product would not corrode the steel containers in which the treated waste was stored. To his surprise, Wagh discovered the steel was passivated by the Ceramicrete and came up with the idea to spray the material as a thick coating on steel components.

“CeraStrata is a result of this evolutionary thought,” he says. “The product is significantly different from Ceramicrete. It is optimized as an all-ceramic coating, but the concept remains the same.”

Here’s how it works: an acid phosphate gel provides the passivation layer while an alkaline colloidal gel forms the protective refractory ceramic top-coat. The chemical reactions then occur simultaneously. The spray of the reacting gel produces a thin coating, about 10 to 30 mil thick, thus rendering the metal substrate less susceptible to corrosion.

If damage occurs on an out-of-reach area of the structure, “it is a lot easier to repair that by applying the ceramic coating locally rather than removing the existing paint and redoing the surface with polymer paint,” Wagh says. “CeraStrata can save significant maintenance costs in the wind industry.” WPE

Filed Under: News, Offshore wind

Is this product available? I cannot find the manufacturer’s website.

Thanks