John Ugland / Technical Account Manager / Renewable NRG Systems

What makes a good condition-monitoring system for the wind industry? One that lets users derive operational value.

We could argue that hardware, sensor placement, and storage servers all play a critical role in the value chain of CMS, but what is really important in a condition monitoring system today? The information it delivers and how a CMS delivers this information to a user is critical.

Understanding the user

The adoption of vibration-based condition monitoring has grown rapidly in the wind industry. In fact, it has outpaced the highly skilled labor necessary to interpret traditional vibration data. Effective maintenance programs require multiple stakeholders. At the wind farm, there are technicians and site managers. In the back office, there are asset managers and reliability engineers.

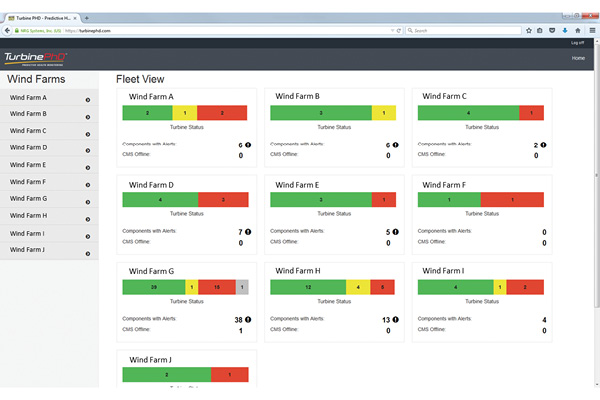

The TurbinePhD condition monitoring system provides a Fleet View for high-level information for many wind farms. For instance, Wind Farm C has only 2 components in alert. But things are not so good at Wind Farm G, with 38 components in alert.

Renewable NRG Systems recognized the skill shortage as an opportunity to redesign the CMS user interface. The company has launched a new, easy-to-use UI this summer with the intent that anyone involved in the maintenance of a wind turbine could easily access, use, and understand the information provided by the CMS. We focused on making turbine health information accessible to all levels of an organization; it’s not just a tool for a select group of vibration analysts.

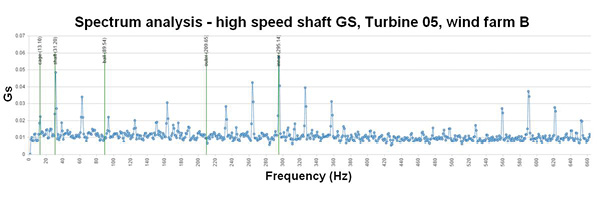

The spectrum analysis identifies significant vibrations and the rotating components responsible for the peaks.

Fleet management

Most companies operate in a lean mode these days, so an effective CMS must let users get to the information they need as quickly as possible. A top level, Fleet View screen, shows all monitored turbines in one view and immediately lets a user focus their resources where they are needed most.

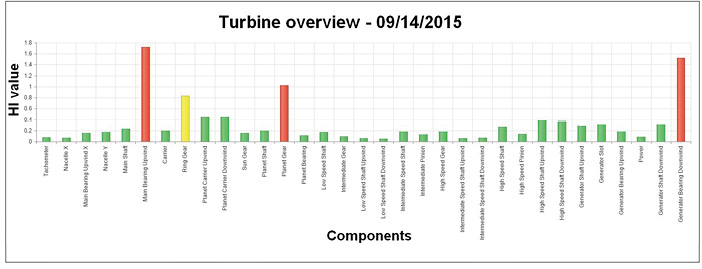

The Turbine overview provides an easy to read evaluation of a particular turbine. For this unit, the easy-to-recognize red bars are calls-for-attention for the Main upwind bearing, a planet gear, and the downwind generator bearing.

Beyond automated email alerts, users can check the UI to see if there are alerts that have not been acknowledged. Acknowledging an alert means it has been seen, validated, and an action plan may be in place. This feature is especially important with multiple stakeholders involved in the wind turbine’s maintenance. For example, a site manager could view and acknowledge all the alerts for their wind farm, while a reliability engineer (responsible for multiple windfarms) could verify that action has been taken.

Accessible and actionable information, at the right level

Traditional vibration data historically involved a lot of squiggly lines. To the trained individual, those can tell a complete story. The Spectrum analysis graph offers an example of a classic bearing inner-race fault, complete with shaft-rate sidebands.

In the previous illustration, the health indicator or HI for the downwind generator bearing indicated an ailing component. Are other generator bearings reaching a particular point in their life? The CMS can pull that information from across the wind farm and display it for evaluation.

But is such information actionable? Is it accessible? Yes, for the vibration analyst, but probably not for the site manager or even a reliability engineer. In a well-structured maintenance program, those are the people that need that actionable information.

Using graphical icons and automatically calculated, statically-based Health Indicators (HIs), such as those in the illustration Turbine overview, site managers without vibration experience can review the health of a turbine’s drivetrain (from their desktop, phone, or tablet) and determine whether or not they need to take corrective action.

Or perhaps a reliability engineer may need to investigate whether or not there is a serial problem: is the bearing defect contained to only one turbine or does it affect more of the population?

A vibration-based CMS doesn’t have to be exclusive territory. Empowering all stakeholders responsible for wind turbine maintenance yields the most effective maintenance program. TurbinePhD provides these features, and more, to end users at all levels in a wind turbine’s maintenance cycle.

Filed Under: Featured