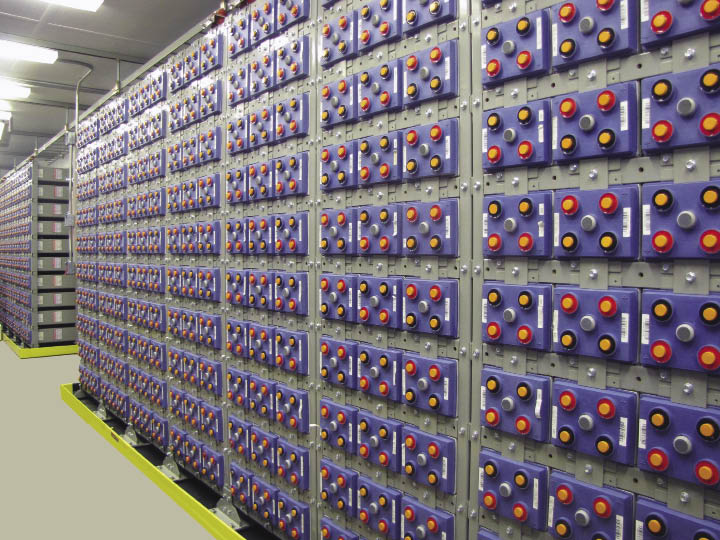

Flat plate, valve-regulated batteries are installed in a Vermont facility. It’s also equipped with an environmentally friendly state-of-art fire suppression system. But before a fire can break out, says EnerSys’ Kulesky, eight disconnects would break the battery into different strings, so it would disconnect from its load and then itself. In this way, should a short circuit occur, there would be no high voltage with which to contend.

Recent airline problems with Li-ion batteries have some asking: Are we expecting too much from this chemistry? Traditional battery manufacturers are answering with: Maybe. The topic of energy storage is important to the wind industry because a sufficiently sized battery can stabilize the grid with controlled ramp rates.

One tested power storage system comes from a 100-year-old manufacturer of traditional batteries, EnerSys and its recent OptiGrid Stored Energy Solutions. “The company has a variety of different technologies and has built large batteries for utilities,” says EnerSys Director of Commercial Marketing for Telecommunications, Utility and New Technologies Mike Kulesky. “A lot of demo projects have proven energy storage works for utilities but only at a certain price. Some problems we see are just that companies putting the storage equipment together are not necessarily battery people.”

Kulesky says his company partnered with Dynapower to handle the electronics. “They are the ac experts and we handle the dc platforms. We look at many different possibilities when an application arises and focus on a handful of solutions that will fit the customer needs.”

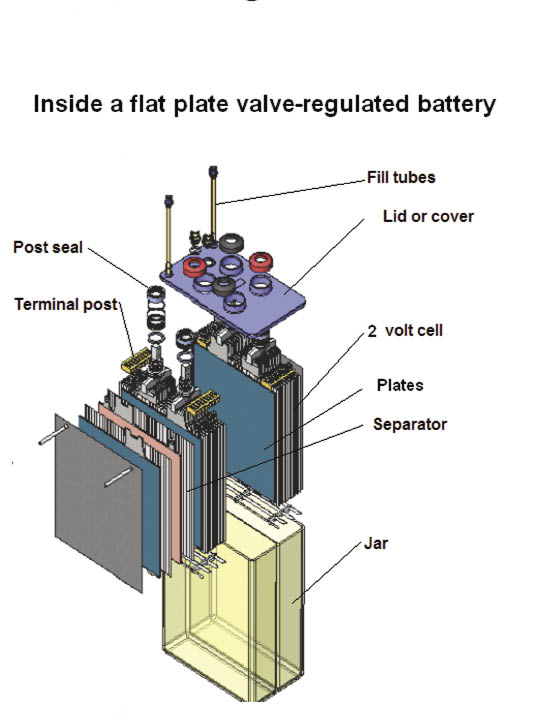

Many possibilities come from many chemistries. “We have nickel-cadmium batteries and are working on some nickel-zinc chemistries. We also have Li-ion, flat plate valve regulated, flat plate valve regulated gel, flooded flat plate, and tubular flat plate,” he says. A valve regulated battery means it uses an absorbed glass mat between positive and negative lead plates. The electrolyte stays in the flat mat and it recombines oxygen in the process. Another feature, a pressure vent, lets pressure escape if too high, but that comes from rare overcharging.

Within the flat plate, value-regulated design, there are 17 different products from 100 to 2,000 Ah. “So if someone needs a 4-MWh battery, there are several ways to build it,” he says.

Kulesky cautions that if someone says they are battery agnostic, be a little leery. “What you want to hear is that they are battery intelligent and know how to treat a battery, how to measure the battery charge, and how they might deal with one failing cell before a major event occurs.”

A demo facility in Vermont, built without government support, shows a 1 MWh battery that can output up to 1.5 MW for short periods. Presently, it is connected to a factory and serves as a resource to maintain the supply of electricity to the manufacturing operations during periods of utility curtailment when electricity is diverted to power the local ski lifts and snow-making machines. A grid connection is scheduled.

“The battery can provide 1 MW for an hour or 250 kW for four hours, and combinations of this sort. We’ll use it as a demo to prove it works for the different requirements that potential users would have,” he says.

Kulesky adds that the Vermont facility has everything possible to show a variety of different safety features, including hydrogen detection equipment inside the unit. It is self-contained to meet requirements of local ordinances along with the disconnects and a balancing circuit to improve cycles, recharge times, and overall life.

Flat plate is the most versatile chemistry. “We can do more things with it and it has reasonably high energy densities, so we can put it in a smaller footprint than others,” he says.

The speed of charge depends on the current going into the battery. “That is part of the charge algorithm, and it depends on the voltage level, and how deep the battery is discharged. The shallower you discharge the battery, the faster the cells can recharge,” says Kulesky.

The battery can handle deep discharges and recharges from 1,500 to 2,000 cycles. For other technologies that are less energy dense, we can do upward of 3,000 cycles. “You can get to 5,000 shallow discharge cycles but that would be more for power quality or ramping. If the wind slows, you want to be able to ramp up generation and you only need some 15 minutes to do so,” he says.

Companies are looking at this technology as an uninterruptable power supply, so that operations can keep functioning should power go out. And it gives a comfort level and at a more reasonable cost. And companies can do their own maintenance on this which could include cleaning and tightening cable connections, conducting visual inspections for corrosion, and measuring voltage and test loads. WPE

A few battery safety features

EnerSys’ Mike Kulesky says an array of batteries from his company will sport several safety features. For instance, the array will:

- Disconnect “on command” into several strings for safety and maintenance

- Monitor key attributes at cell level and respond accordingly

- Identify when a battery or strings of batteries need balancing

- Dc ground-fault monitoring and protection provide safety, security, and reliabilit

- Heats and cools cells to optimize the battery operation

- Designed in shelter-safety features include fire suppression, spill containment, and gas detection

Filed Under: Energy storage, News

Great article!

We believe the OptiGrid Stored Energy Solution will allow leaders in the Utility sector to better support the industries growing demand and challenges with a customizable, cost effective and regulation-compliant system.

Key features include:

Reduce strain on transmission and distribution infrastructure

Manage grid-level storage needs

Improve power quality and efficiency

Integrate renewable energy resources

Moderate peak demand