The drawing of an anchor bolt at work shows more detail. The void is called out just above the concrete in the the drill hole.

Joseph K. Alter/ Con-Tech Systems LLC/ www. contechsystems.com

Conventional wind-turbine foundations are large pads of concrete some 20-m across and 2 to 3-m deep. These spread-footing foundations consume up to 500 to 700 cubic meters of reinforced concrete.

A recently developed foundation system is more efficient and environmentally friendly. It consumes up to 40% less concrete and up to 70% less reinforcing steel than traditional versions. The patented design (Canadian Patent No. 2,551,712) uses a Groutable Void Form (GVF) post-tensioning (PT) technique. In it, a void is created between the top of the ground anchor and the bottom of the concrete cap.

Ground anchors are 30 to 40 ft. long steel tendons that grab deep into the soil and rock below a foundation where they generate friction or grip to hold the foundation rigid against the overturning loads on the tower.

Post-tensioning the ground anchors allows the void to collapse in a controlled manner pulling the cap down. The anchor moves about 0.125 to 0.25 in. Thereby transfering post-tensioning forces through the ground anchor to mobilize soil resistance. After the anchor is post-tensioned and locked off, the void is filled with a cementitous grout. Installed ground anchors are all proof tested to their maximum load and then locked off to a lesser load–the working design load.

The idea is to have the post-tension forces in the anchor always exceed any potential forces induced in the foundation by the overturning moments. The ground anchor then resists compression as well as tension forces thereby increasing foundation stiffness and eliminating cyclic loading in the soil. Fatigue stresses also become nil.

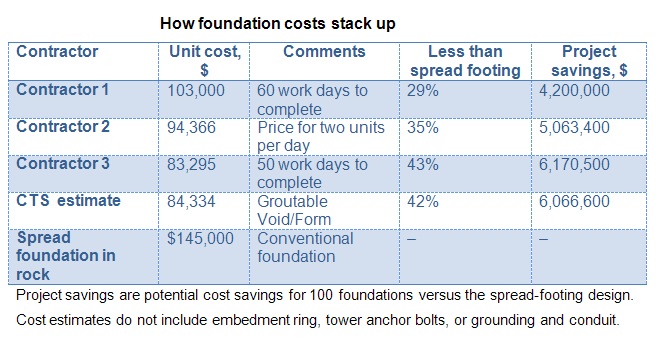

CTS engineering estimates are compared with spread-footing costs and presented in the table How foundation costs stack up. Construction cost estimates for a conventional or spread-footing foundation are from three qualified foundation contractors and provide evidence of the new foundation’s economic and environemental advantages.

WPE

Filed Under: Construction, News, Towers

The safety of foundations and piles can with the online measurement of stress are measured in the concrete during the operation of the wind turbine. More information:

http://de.slideshare.net/fmj2/wind-turbine-foundation-stress-strain-amp-bolt-measurement-using-ultrasonics

http://www.ibj-technology.com

You are right: 250W is not much considering it is the peak output of the turbine. It might produce enough power to keep cell phones and tablets charged. I have to admit it, instead of small wind turbines, several solar panels make for sense for a roof installation.

FJM has posted two urls that may hold useful information for wind farm construction crews and foundation engineers.

The first one (http://de.slideshare.net/fmj2/wind-turbine-foundation-stress-strain-amp-bolt-measurement-using-ultrasonics) is to a series of slides that discusses measuring stresses in concrete, in particular, a wind turbine foundation.

The second url is for the company that manufacturers the sensors.