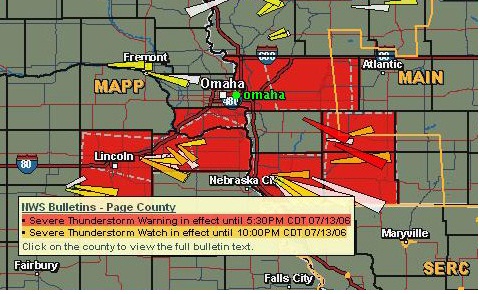

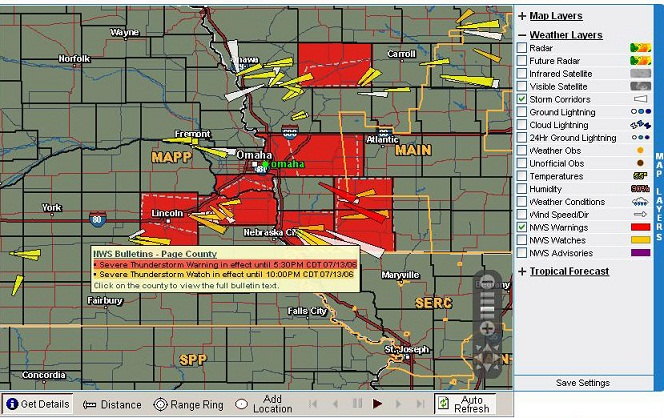

Although the map is for the Omaha region, its information is similar to that received by crews at the Langdon Wind Energy Center. In addition to watching storms as they pass through their region, crews at Langdon use hourly and 10-day forecasts to schedule routine maintenance. The weather services come from Telvent

North Dakota’s flat plains and strong, steady winds make it ideal for wind farms. But this part of the country is especially susceptible to extreme weather conditions. Summer brings the threat of lightning strikes to the 300-foot tall turbines and brutally cold temperatures are commonplace in winter.

The Langdon Wind Energy Center operates a 133-turbine facility owned by NextEra Energy Resources and capable of producing 199.5 MW. To ensure the turbines operate at peak-efficiency, a team of 12 technicians perform routine maintenance duties and are on-call 24/7 in case of an emergency.

“In addition to lightning risks, we don’t send out crews if it’s colder than -28°C,” says Bill Campbell, plant leader for Langdon Wind Energy Center. “In cases of extreme cold, we only send out crews when absolutely necessary.”

To help navigate its weather challenges, the Wind Energy Center subscribes to MxVision WeatherSentry Online Wind Energy Edition professional package. Its services come from IT company Telvent. By accessing an internet-based platform, the Center stays on top of changing weather conditions that endanger operations.

For a complete view of approaching severe weather, the Center monitors radar and tracks storms, wind, and lightning on one centralized online dashboard. It features a weather map with layers that let personnel look at the specific weather information most important to its operations. This includes National Weather Service (NWS) warnings, watches, and advisories. Another layer includes custom areas of maximum impact based on parameters set by the Center to reflect how weather is affecting the exact location of its turbines.

In addition to the online dashboard, the Center uses a mobile alerting system to view current and future conditions. To stay one step ahead of the weather, employees also have access to all of the online dashboard’s weather information on their mobile phones. Additionally, personalized alerts are sent instantly to employees’ phones when severe weather nears user-defined alerting parameters. This is especially important for field technicians performing maintenance tasks.

“We let the technicians know when lightning has been detected within 60 miles,” said Campbell. “When lightning is detected within 30 miles, we require crews to evacuate the turbines.”

The mobile alerts are fed from an alert manager that provides instant notification of significant weather changes within their coverage area. When weather conditions, such as wind-speed changes or when the NWS issues a watch, warning, or advisory, an audible alarm goes off through the online dashboard. “The system alerts us by sounding a siren letting us know we must either monitor weather conditions more closely or evacuate crews,” says Campbell.

The most critical weather component for the Center is the Lightning Manager. Receiving advanced warning of real-time lightning strikes from real-time lightning data is much safer than predictions that can lead to false alarms or delayed reporting after lightning has already struck.

Five Langdon crew members use the system. They can access weather data in the office, on the wind farm, and at their homes. “If my guys get called in over a weekend, I can log on from home to find out what’s going on with the weather and ensure their safety,” says Campbell

In addition to watching storms as they pass through the area, Campbell and his technicians use hourly and 10-day forecasts to schedule routine maintenance. This allows for more efficient planning. For example, a wind turbine should not be slated for cleaning with a rain storm impending.

Although this type of renewable energy relies on the wind to generate electricity, too much wind can also impact operations and safety. If winds are too strong, crews cannot work on the turbine’s hub. Although each turbine has a wind speed indicator, Langdon Wind Energy Center also relies on Telvent for wind speed and direction to ensure optimal safety.

As a result of implementing an advanced weather information service, Campbell and his technicians have been able to improve operational efficiencies while ensuring the highest level of safety. “Safety is a shared value at our company,” said Campbell. “We rely heavily on the real-time weather information to keep our technicians safe and operations running efficiently.”

Filed Under: News, Safety

I would be interested to hear if any type of lightning surge suppression or protection is employed in these wind turbines. I would imagine they have something employed given the frequency of storms.

As an insurance company we need to know more about wind towers/turbine and solar units, as we get asked to insure them.

Are there surge arrestors installed, recommended in the line from the tower to the user/house, dairy barn, etc?

What are some of the most common weather related activities that damage towers ?

and which is more prevalent ?

wind, lightning, fire, vandalism, other?

Is there any data available for this info or web sites?

Does the state regulate construction, site location of private wind towers?

What state government office could provide info on private wind tower regulation?

Thank you in advance for any help you can provide.

Mr. Bossert:

You’ve discovered in one brief article the complexity of the wind industry. Rather than me guess at answers to your question, I’d suggest contacting companies such as Erico in Solon, Ohio. They manufacture lightning containment equipment and grounding designs for tall towers. Website: http://www.erico.com.

Other questions could be answered by wind farm developers such as RES America in Colorado, and Kleinfelder Engineering, corporate office in San Diego.

Paul Dvorak