Robots may soon change the way routine maintenance is conducted on wind turbines, leading to fewer up-tower climbs for wind technicians. Given the risks and high cost of conventional rope or aerial lift access for turbine O&M, this is promising news for the industry — and particularly for the offshore wind sector, which typically means harsher winds and riskier conditions at project sites.

Researchers at Sandia National Labs test crawling robots to detect wind-turbine blade damage with the aim of driving down wind energy maintenance costs of wind energy. (Photo: Randy Montoya | Sandia Labs)

Autonomous, robotic devices that can reliably scale a wind-turbine tower and crawl on blades offer significantly safer, up-close inspections that rival human counterparts. One benefit to robots is the inspection tools they may carry, including cameras, sensors, and artificial intelligence.

For example, in one current research project, Sandia National Laboratories is equipping a crawling robot with a scanner that will search for hidden damages inside wind-turbine blades. The reason? According to mechanical engineer, Joshua Paquette, who’s a part of Sandia’s wind energy program, current blade inspection methods rarely catch damage soon enough to minimize costs or repairs.

“In these visual inspections, you only see the surface damage,” explained Paquette. “Often though, by the time you can see a crack on the outside of a blade, the damage is already quite severe. You’re looking at a very expensive repair or you might even have to replace the blade.”

Sandia showcases b-roll video footage of its robotic crawler, performing a test inspection on a damaged blade segment here. Routine inspection is critical for keeping wind turbines in service and maximizing clean-energy generation, says Paquette.

Robowind, an early-stage robotics company, agrees. It recently partnered with professors from California State University to develop robots and robotic tools for wind-turbine blade maintenance. However, the team believes robotic devices can do more than inspect blades.

Robowind is developing devices with the capabilities to inspect, clean, sand, paint, and repair. The latter includes applying blade coatings, leading-edge protection, or installing vortex generators (VGs). VGs are aerodynamic devices sometimes applied on turbine blades to optimize wind generation.

The MIMRee wind O&M initiative is using a six-legged crawling repair robot, called the BladeBUG. Watch a video about the research project here.

A two-year UK-funded initiative also began this year to prove offshore wind O&M can be safely and successfully carried out by autonomous vessels, crawling robots, and drones. The MIMRee (Multi-platform Inspection, Maintenance & Repair in Extreme Environments) project is relying on experts in the fields of robotics, artificial intelligence, non-destructive testing, marine and aerial engineering, and others.

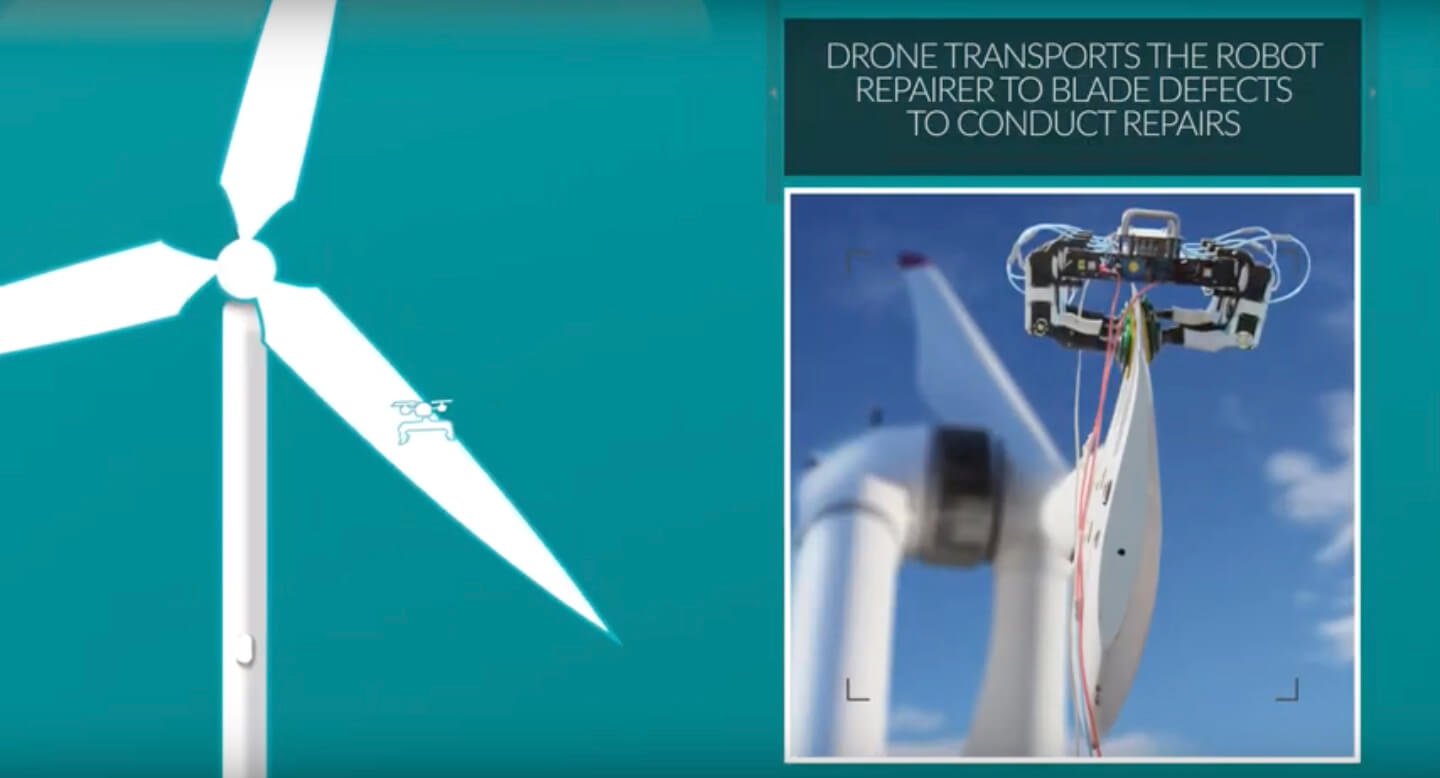

The MIMRee researchers are employing autonomous vessels to initially scan and map the wind turbines at a project site. Onboard drones will then conduct visual-imaging inspections of the blades and transport crawling robots to the blades to make repairs.

The robots may also use an electronic skin (developed by high-tech startup company, Wootzano) to “sense” or “feel” a blade’s surface and collect structure data.

The end goal is to develop a holistic digital and robotics system that’s capable of planning, communicating, sharing data, and working together on complex sequences of maintenance tasks. The advanced robotic system is expected to save a typical wind farm about $33 million in O&M over its lifetime.

Filed Under: Featured, O&M

Appreciate the development in robots being used at such a height where only cranes and rope access were used. Today this appears as a science fiction which will turn to reality and we will be having such devices on our wind farms performing the repair work up-tower.

I would be glad to see some of these in real robots.