ROMO Wind’s iSpin uses three ultrasonic sensors mounted at the spinner. Sensors are installed in the front of the wind turbine, where the wind hits first.

In spring 2016, Energiekontor installed the spinner anemometer technology iSpin, initially on two of seven Vestas V80-type turbines. The exact wind measurements taken directly at the spinner were intended to determine whether the turbines in the Lower Saxonian wind farm were aligned for the best possible yield. The result of the measurements: both of the 2-MW turbines showed significant yaw misalignments of 8.0 and 7.9°.

After correction, the turbines delivered 3.5 and 2.9% more production. Now the wind-farm operator plans to equip further turbines with the iSpin system.

“The iSpin system is very lucrative for us: with the extra yield we gain, the investment pays off after less than three years,” says Carsten Schwarz, Head of Operations of company-owned wind farms at Energiekontor AG. As one of the wind energy pioneers, the company has developed 102 wind farms with more than 580 turbines. Its own portfolio comprises 33 wind farms with 269-MW rated output.

At Thüle wind farm, one freely-streamed and one shadowed turbine were equipped with the iSpin measurement technnology. Schwarz explains: “The iSpin technology has fully met our expectations. We also plan to install the system on other turbines because we see enormous potential for further production increase. At Thüle wind farm alone we expect to gain 20,000 Euros more revenue through better measurement data. The data of the turbine manufacturers is not sufficient for that.”

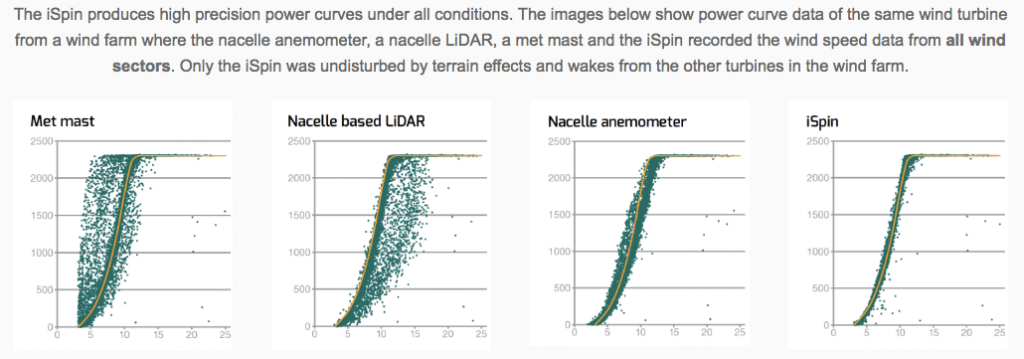

Prior to now, wind speed and direction have usually been measured behind the rotor on the wind turbine’s nacelle, where turbulence can lead to inaccuracies.

The ROMO Wind iSpin system uses proven ultrasonic technology to measure wind where it first hits the wind turbine – directly at the spinner. In this way, operators gather accurate information on the wind conditions in front of the rotor. This enables them to check whether their turbines are aligned for the best possible yield.

At the same time, the data allows for optimized wind farm management and load reduction, which prolongs the total life of the turbines.

“With iSpin, wind farm operators can measure and monitor the actual earning capacity of all their turbines any time during their lifetime. The effects of changes such as component exchange and optimization measures are traceable,” says Jens Müller-Nielsen, Managing Director of ROMO Wind in Germany. “iSpin measurements are independent from environmental factors, so operators can compare performance data of different turbines, which is essential for active wind farm performance management.”

The iSpin technology was developed by the Technical University of Denmark (DTU) and tested continuously since 2004 until it came onto the market in 2013. iSpin is a wind measurement technology which is not dependent on a specific manufacturer, and is designed for permanent installation. The iSpin system has been incorporated into the international IEC 61400-12-2 standard for measuring the absolute power curve.

ROMO Wind at WindEnergy in Hamburg, September 27 to 30, 2016; Hall A1, Stand 425.

Filed Under: News, Pitch & yaw, Projects, Sensors