Danish machining company CNC Onsite has developed a patented method for repairing, not replacing, yaw rings on wind turbines on site. The process doesn’t require disassembly on the turbine rotor and nacelle necessary for replacing yaw rings. The teeth on yaw rings can wear down over time, and they’re necessary components for power production. “This…

Parker develops bladder replacement kits for wind turbines

Parker Accumulator and Cooler, a motion and control technologies manufacturer, has developed a line of replacement kits for bladder-style accumulators used in wind turbines. The kits let wind turbine technicians replace bladders in the field, avoiding potential downtime and power capacity disruption. The bladder replacement kits are engineered with rubber compounds that Parker formulated specifically…

Pitch control valves: Built to last longer and lower O&M costs

By Eduardo Gimenez, CEO; Len Kaster, PE, CFPE, technical sales support; Madeline Hanley, technical marketing and sales; ALA Industries The United States is a leader in wind energy — wind generates 7% of the electricity Americans use. But it’s still behind the Europe Union, which receives 12% of its electricity generation from wind turbines. The…

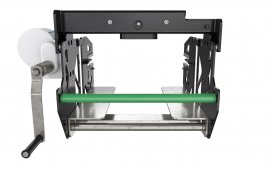

Specialized tools revolutionize wind turbine brake maintenance

By James Woods, Senior Project Manager, Svendborg Brakes – a brand of Altra Industrial Motion Corp. Some large wind turbines feature a yaw brake. Heavy and difficult to maintain in the field, lifting and positioning brakes is a sizable challenge in confined spaces, but maintenance is critical to minimizing operational downtime. Once working high up…

Schaeffler combines torque and condition monitoring into a single system

The long-term development partnership of Schaeffler and Bonfiglioli, provider in yaw and pitch drives for wind turbines, has lead to the creation of a compact Industry 4.0 solution package. Schaeffler has combined two of its proven measuring systems, the SmartCheck and the TorqueSense, to create a new condition and torque-monitoring system. While the vibration diagnosis…

Are your turbines facing the wind?

Renewable energy company Clir Renewables has developed software that uses leading wind industry expertise, data science, and machine learning to quantify and provide actionable insights to help mitigate the lost energy production caused by both static and dynamic yaw misalignment. The concept of yaw misalignment is unique to the wind industry; if the wind always blew in…

Reducing O&M costs with ultracapacitors in emergency pitch-control systems

By Joshua Hitt, Senior Product Line Manager Maxwell Technologies While wind-farm operators work to optimize turbine performance and uptime, it’s inevitable that certain components will demand greater O&M attention. One aspect of turbine maintenance that typically causes multiple downtime hours per month is battery-based emergency pitch-control systems. Pitch control is an important turbine component used…

iSpin provides 3% more production at Thüle wind farm by detecting turbine yaw misalignment

In spring 2016, Energiekontor installed the spinner anemometer technology iSpin, initially on two of seven Vestas V80-type turbines. The exact wind measurements taken directly at the spinner were intended to determine whether the turbines in the Lower Saxonian wind farm were aligned for the best possible yield. The result of the measurements: both of the…

How are motors and drives used in a wind-turbine nacelle?

A wind turbine needs yaw brakes to hold the rotor facing into the wind. If the turbine is not facing directly into the wind, it is not producing at full capacity. When wind direction changes, a turbine’s controls instruct its yaw motors to reposition the nacelle. “In theory, this could be handled by one large…

Where are hydraulics used in a wind turbine?

The muscle that pitches wind-turbine blades can come from either a hydraulic or electric device on most turbines rated at and below 2.5 MW. But for turbines over 3 MW, the job of pitching blades more often falls to hydraulics. And hydraulics can handle more. “Hydraulics in wind turbines usually refers to the assemblies for…

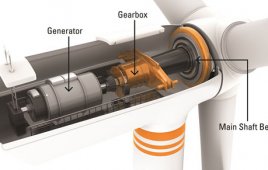

Turbine components: bearings

Where are bearings used in a wind turbine? Although bearings are used many places throughout a nacelle, such as in the yaw and pitch bearings and on the generators, those on main shafts and gearboxes are most problematic. In main-shaft bearings, modular wind-turbine designs commonly use spherical-roller bearings (SRB) units that are more than 1m…

SKF to supply wind turbine bearings to ReGen Powertech

SKF has signed a strategic agreement with ReGen Powertech, a leading wind turbine manufacturer in India. Under the terms of the agreement, SKF will supply pitch and yaw bearing sets and mainshaft bearings for the company’s 1.5-MW wind turbines. Shishir Joshipura, Managing Director and Country Head, SKF India, said, “This agreement positions us as a…

A better pitch bearing might include a sprag clutch

The problem with pitch bearings is that they don’t move much, just back and forth in a narrow angle. This leads to metal-to-metal contact between rolling elements and races. It is a frequent possibility that leads to false brinelling. It’s a kind of damage from fretting and appears as wavy, chipped, or corroded damage on…

Altra Industrial Motion acquires Svendborg Brakes

Altra Industrial Motion Corp. says it has closed on the acquisition of Svendborg Brakes A/S and S.B. Patent Holding ApS (together “Svendborg”), a global manufacturer of premium quality caliper brakes. Headquartered in Vejstrup, Denmark, Svendborg provides engineered braking systems for a wide range of industrial markets including oil & gas, mining, wind power, marine, metals,…

New safety brake for small wind turbines

Based on 60 years of experience in clutch- and brake technologies, Suco Technologies has developed a safety brake which can reliably protect small wind turbines against storm damages due to excessively high-wind speeds. Small wind turbines are designed mostly for low- and medium-wind speeds. The dangerous wind speeds from storms and hurricanes can, damage or,…

Renewable-energy active hydraulic brakes now GL approved for wind

Several hydraulic-brake products from Carlisle Brake & Friction have been approved by Germanischer Lloyd (GL) Industrial Services. The brake models, WBA1-90-SC, WBA4-90, and WBA6-120, offer innovative and cost-reducing features such as next-generation friction and hydraulic systems. As part of the accreditation process, the GL representative ensures that the installation, operation and maintenance manuals are observed…

Brakes 101

Slowing and halting an 80-m-turbine rotor involves converting its kinetic energy into heat. Of course, there are several design decisions here. Rotor brakes control overspeed, and provide parking and emergency braking. These brakes can mount on the rotor or low-speed shaft, on the generator (high-speed shaft), and both shafts in some cases. Low-speed-shaft braking is…

Cylinders for hydraulic pitch adjustment

German company Liebherr is offering their hydrau-lic cylinder for hydraulic pitch adjustment in wind turbines to the American market. The company offerso both electromechanical pitch adjustment with gearboxes as well as hydraulic pitch adjustment with the corresponding blade bearings as a full system. Cylinders are supplied in accordance with a customer’s particular requirements, in-cluding piston rod heads and integrated stroke measuring systems.

Yaw brake earns GL certification

A yaw brake model, FHGE, comes in three models, -77, -90 and -120. Each features a small air gap and few moving parts for a short response times and fast braking. Additional features include a large brake-pad area and low brake-disc temperatures. For the wind-energy market, the company manufactures rotor brakes that generate braking forces…

No friction pads on these pitch and yaw brakes

MagnaShear motor brakes use oil-shear technology for longer service life even in demanding applications such as pitch and yaw drives and generator-holding brakes in smaller wind turbines. The proven technology transmits torque between lubricated surfaces – thereby eliminating wear on friction surfaces. A patented fluid recirculation system dissipates heat – a common problem in dry-braking…