The requirements of offshore and onshore wind turbines fit well into the Lafert Group’s portfolio of industry sectors due to the experiences gained in over 50 years of building motors for special applications. The company has motors installed in over 20,000 nacelles worldwide.

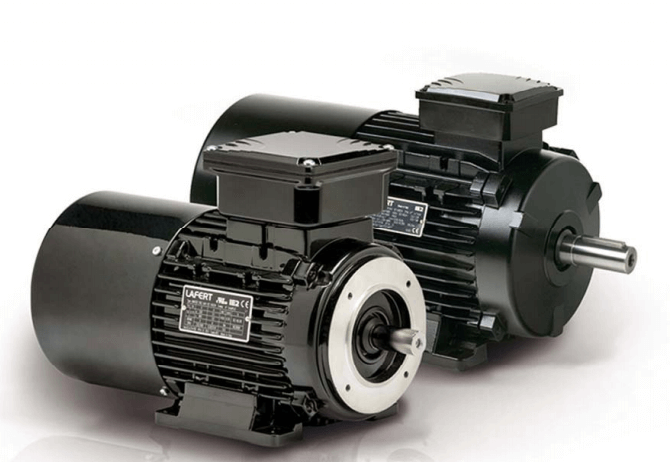

The design range of Lafert motors includes reliable ac and PM (permanent magnet) motors for wind-industry applications with an efficiency level depending on specifications. For instance:

- IE2, IE3, IE4, and IE5

- Single speed and two-speed ac motors or dedicated multi-speed PM motors controlled by a frequency converter

- Brake motors with ac or dc brakes

- Mechanical and electrical adaptations for specific applications

- Mechanical components and paints delivering high corrosion protection for work offshore.

Where there is a focus on efficiency and weight, Lafert offers IE4 and IE5 PM motors. In general, PM motors are half the weight of ac motors of a similar power and size.

Motor applications within the wind industry include yaw and pitch drives, hydraulic oil and power packs, pumps, ventilations, and service lifts.

The ability to friction-weld motor shafts with magnetic and stainless steel materials mean that corrosion of critical components is a concern of the past. In addition, mechanical components and paint systems have been tested thoroughly with an in-house life cycle, climate-chamber test for arduous environments to a point that we exceed expectations in many areas.

For offshore applications, Lafert can achieve a corrosive category of up to C5-M(H) which means our corrosion protection system meets the highest requirements that guard against water condensation and neutral salt spray as defined in DS/EN ISO 12944.

The nacelle cutaway shows several application areas for Lafert motors. Yaw motors are visible front and center, a hydraulic system is just above them, and the service crane in the back. Less visible applications include the ventilation system and motors to drive the pitch system in the hub.

Motors for yaw & pitch drives

Blade pitch and nacelle position are critical to extracting the maximum amount of energy from the wind. The yaw mechanism requires reliable and efficient components.

Lafert yaw-brake motors focus on a soft start based on a dedicated winding design to secure a long life for the yaw gear. The application of stainless-steel brake disks gives the ac or dc brake strong corrosion protection.

Motors for coolers & hydraulic pumps

These devices often operate in harsh environments which call for high quality on special finishes. Anti-corrosion applications require strong customization of the motor components, such as the shaft, flange, or electrical design.

The different applications in the nacelle require driving and controls of hydraulic pumps for onboard actuators, such as for pitch positioning, along with cooling and lubrication tasks.

Filed Under: O&M