This article is provided by the Lake Erie Energy Development Corp.

The potential for offshore wind power generation in the U.S. is staggering. At a projected 4,223 gigawatts (GW) of electric generating potential (with the Ohio waters of Lake Erie alone accounting for more than 50 GW of that power), offshore wind offers a viable, untapped opportunity for large-scale clean energy projects that produce zero emissions in operation, consume no water, and displace the generation from some of our nation’s dirtiest power plants.

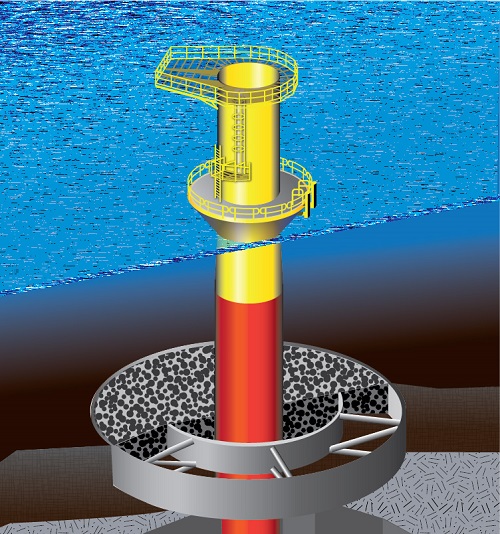

The conventional monopole awaits a turbine in the North Sea. The design has improved and adapted for manufacturing in the U.S.

But the U.S. lags woefully behind the rest of the world in offshore wind power generation. With at least 80 offshore projects in operation or under construction (powered by more than 1,900 wind turbines), Europe leads the world in design and deployment of offshore wind farms, having the backing and support of key developers and governments over the past 30 years to master the many intricacies and challenges related to offshore wind.

Back home in the U.S., offshore wind development is in its infant stages, as federal, state and local governments, along with wind farm developers, have just taken the first steps in a quest to harvest electricity from the consistent and unobstructed wind that bellows off the coast.

LEEDCo Wades Into Lake Erie with “Icebreaker”

As a front-runner in the race to develop one of the first offshore wind projects in the United States, the non-profit Lake Erie Energy Development Corporation (LEEDCo) is currently developing a demonstration project called “Icebreaker” that will solve the challenges of deploying wind turbines in a freshwater environment. With a design consisting of six wind turbines positioned seven miles off the coast of Cleveland, Icebreaker will become a catalyst to building an offshore wind industry in Ohio and the Great Lakes region. And with new industries and new markets come old challenges, according to Eric Ritter, LEEDCo communications and strategy manager, who noted that the natural approach to manufacturing components for such a project would traditionally come from overseas, where the offshore wind industry is already well established. But this is where the tide turns. “Our options were to either look to Europe and hire suppliers that had the specific manufacturing capabilities, or go the local route and identify those manufacturers with similar capabilities, then hone those capabilities to meet our offshore standards and requirements,” said Ritter.

Identifying qualified, local suppliers for offshore wind

Building a U.S. supply chain is precisely the direction that LEEDCo has taken for Icebreaker. In 2012, the organization assembled a team of international firms with expertise in offshore wind and partnered them with local companies interested in expanding into this emerging market. Together, they developed conceptual engineering designs for the structural foundations that would support Icebreaker’s six wind turbines.

AT&F has the machinery capable for rolling steel sheets into cans, sections of the optimized monopole designed, for work in Lake Erie.

With those designs in hand, LEEDCo organized a special workshop in Cleveland and invited a dozen regional steel fabrication and construction firms that were pre-qualified by WIRE-Net’s Global Wind Network (GLWN) to review the designs and offer feedback. “Our goal was to identify a foundation type that could withstand Lake Erie’s harshest winters and could also be fabricated by American companies,” said Ritter. “Based in part on the feedback from the local supply chain, we ultimately chose the monopile foundation. Now we’re working to complete the detailed design and optimize it for the existing capabilities of our domestic steel fabricators. The United States, and our region in particular, has some of the best steel fabrication companies in the world. Our design will enable them to compete against their European counterparts that already have decades of experience in this industry.”

As LEEDCo launches its effort to complete the detailed design of the foundation, the non-profit developer recently announced that it has partnered with Cleveland-based AT&F (formerly American Tank & Fabricating) to represent the interests of U.S. fabricators. The company will advise LEEDCo’s engineering team to ensure that the final design matches U.S. standards and specifications. As one of the country’s top metal fabricators, AT&F has serviced the heavy industrial, energy and defense industries since 1940.

This will be the first monopile foundation designed from the ground up to be built by American companies and installed in American waters.

“We can roll the steel for this project and it’s right in our backyard,” said AT&F president and CEO Michael Forde Ripich. “LEEDCo was instrumental in bringing the design development for the offshore foundations to the table and presenting an integrated solution that garners the strength of suppliers from Northeast Ohio and neighboring states and utilizes their existing strengths and capabilities.”

The Icebreaker project represents a major addition to AT&F’s capabilities in the renewable energy industry, according to Ripich. “Conventional energy industries (oil, gas, shale, nuclear) traditionally have been our key growth areas,” he commented. “But there are emerging industries – such as renewable energy — that are outpacing our traditional business. And we’re in at the beginning stages, which is very exciting to us.”

But there are barriers to growth in this burgeoning industry. “The capital investment required to produce components in this industry would require a level of volume to justify a return on the asset,” Ripich said. “So you can’t create a supply base without a commitment to do a lot of work.”

Ripich continued: “AT&F and other steel fabricators with similar capabilities can become strong players in the offshore wind market particularly if we have under used heavy capacity equipment. In recent years we built special capacity to service the nuclear industry, but that industry is faltering in the U.S. So now we have large assets — production space, large steel-rolling machines, heavy welding and assembly capacity — which are transferable to the renewable industry. Additional investment will take time but can grow with the industry if the industry aligns itself with supporting a domestic supply chain.”

Ripich credits LEEDCo with identifying those local manufacturers that can become assets to this new industry. “LEEDCo recognized the underused existing capacity in the region and made the compelling case for a pilot project that could be a good start for us in offshore wind,” he said. AT&F estimates that the pilot project will require 20 to 50 new hires to support the work in Lake Erie.

Furthermore, the collaboration between LEEDCo, AT&F and other Icebreaker suppliers has had added benefits, according to Ripich, who said his company’s introduction into Great Lakes Shipyard (another project partner) through LEEDCo has resulted in collaboration on other projects outside of Icebreaker.

The need to build a local and regional supply chain for the offshore wind industry is vital now more than ever, according to LEEDCo’s Ritter. “There are roughly seven gigawatts of coal-burning power plants set to retire in the next year,” he commented. “Our aging coal fleet faces mounting pressure from low-priced natural gas and tighter pollution standards. And frankly, the energy is just not competitive anymore. The question is how do we replace that retiring capacity? Natural gas is a big piece of the puzzle, but we have to recognize the value of a balanced portfolio of energy sources. The fact is that offshore wind in Lake Erie is by far the most abundant renewable resource in our region, and Icebreaker is the key to unlocking that resource.

“Especially when you consider the regional assets that are already in Northeast Ohio,” such as our ports, our grid infrastructure, our manufacturing companies, and more. The long term market outlook for offshore wind in Lake Erie looks very strong,” adds Ritter.

As for Ripich and AT&F, success will take time. “This is a new market in the U.S.,” he said. “We can certainly bring in components more efficiently than the competition. And if we have the patience to build a supply chain, the benefits will be substantial. This is really an opportunity to break the cycle and develop a localized solution.”

LEEDCo’s approach for developing a domestic offshore wind farm

America’s clean energy policy is intended to further investment in new technologies that offer health, environmental and manufacturing benefits, while supporting the U.S. companies that pioneer those technologies. But great intentions and actual policy implementation sometimes don’t coincide.

Reality is that current U.S. energy policy rarely takes into account the manufacturing component of those benefits mentioned above. The Production Tax Credit and Investment Tax Credit provide investment advantages to developers of clean energy, but ignore domestic manufacturers. Foreign competitors in the clean energy industry benefit from a host of manufacturer-friendly policies and practices that often tilt the playing field in their favor.

Even without the help of these policies, LEEDCo is doing everything possible to lower the market barriers for U.S. fabricators. Of the projects that competed for the U.S. Department of Energy’s offshore wind competition, only LEEDCo found a way to develop and utilize domestic producers across the entire project supply chain, beginning with suppliers in Northeast Ohio and expanding elsewhere in the U.S.

WIRE-Net, GLWN and other pro-manufacturing economic development organizations continue to highlight the need for stronger connections between our domestic energy and manufacturing policy. America deserves clean energy technology which utilizes American-made components.

Lake Erie Energy Development Corp.

www.leedco.org

Filed Under: Construction, News, Offshore wind

Same with the coal, oil, natural gas and nuclear industry, right Keith? They have been feeding at the public trough for way longer than the wind industry. And the nuke industry is 100% dependent on the Price Anderson Act. They need to get profitable without subsidies or get gone. Any of course their biggest subsidy is they get to dump their waste products on people’s private lands and even in their bodies. You want them to stop that, right Keith? They should have to make sure all their waste products stay on their private land or “get gone.”