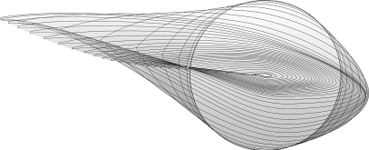

In the first phase of the DOE-funded additive manufactured blade mold demonstration project, Sandia National Laboratories has designed the wind blade that will be built with the new molds (drawing design shown here). One of the 3D-printed molds will be showcased at the American Wind Energy Association (AWEA) 2016 Windpower Conference and Exhibition, May 23 to 26 in New Orleans, LA. Using Sandia’s blade design, Oak Ridge National Laboratory is creating the molds by additive manufacturing.

The 3-D printed molds will be transferred to TPI Composites, Inc., where they will be finished and used to make four blades based on Sandia’s design. Ultimately, the resulting 13-meter blade will be flown on Sandia’s highly modified Vestas V27 turbines at Sandia’s subscale Scaled Wind Farm Technology (SWiFT) facility in Lubbock, Texas.

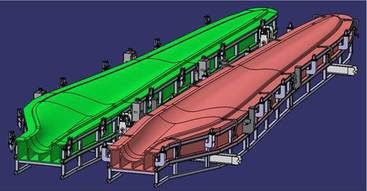

Drawing shows blade-mold fabrication assembly with sections joined together and attached to a support scaffold. DOE WWPTO/AMO.

The first blade of its kind, the National Rotor Testbed (NRT) is a scaled-down version of the nation’s most common 1.5 MW blade. This unique small-scale design will enable DOE and Sandia to analyze turbine-to-turbine interactions cost effectively. EERE’s Wind Program and Advanced Manufacturing Office (AMO) are collaborating on the funding and creation of the blade molds; after the molds and resulting blades are complete, they will be used to research wind facility efficiency at the SWiFT Facility. Project success will enable significant cost savings for blade production as well as agility to test and evaluate emerging designs that can improved efficiency and reduce manufacturing costs.

Filed Under: Blades, News