Scientists and engineers recently celebrated National Hydrogen and Fuel Cell Day.

Sandia National Lab sponsors the 2016 Wind Turbine Blade Workshop

The 2016 Sandia Wind Turbine Blade Workshop will bring together wind energy professionals from industry, academia, and the national laboratories to discuss challenges, issues, and solutions related to wind turbine blades.

Sandia says better data from MET towers avoids issues of nacelle measurements

The real-time operating system can now display live weather conditions for the operator.

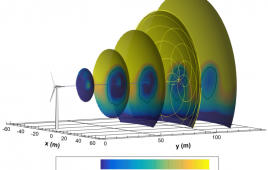

Virtual Lidar model helps researchers plan for the Wake Steering Experiment at SWiFT

During the multi-month field campaign, researchers will collect data to improve high-fidelity wind plant simulation (Virtual Lidar) software and demonstrate novel control concepts.

Wind Turbine Generator a1 returns to power production at Sandia’s SWiFT

WTGa1 will complete all commissioning before the end of May 2016 after satisfactorily operating in high wind conditions. Turbines WTGa2 and WTGb1 will complete commissioning over the summer months.

Sandia Labs showcases partnership with Vestas at the EERE Lab Impact Summit

Renewable Energy Senior Manager Juan Torres participated on a panel at the recent DOE Office of Energy Efficiency and Renewable Energy (EERE) Lab Impact Summit to showcase Sandia Laboratories’ partnership with Vestas.

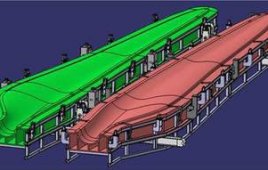

Sandia National Laboratory engineers to showcase their blade design at Windpower 2016

In the first phase of the DOE-funded additive manufactured blade mold demonstration project, Sandia National Laboratories has designed the wind blade that will be built with the new molds.

Sandia report highlights key composite testing trends for more reliable and lower cost wind blade designs

Sandia National Laboratories recently published “Analysis of SNL/MSU/DOE Fatigue Database Trends for Wind Turbine Blade Materials, 2010-2015” by researchers at Montana State University (MSU), a long-time academic research partner.

Sandia’s engineers remount a rotor on one of its SWiFT turbines

Sandia National Laboratories has reached a major milestone by successfully re-mounting a rotor on one of its SWiFT (Scaled Wind Farm Technology) wind turbines, a heavily modified Vestas V27, at the SWiFT facility.

Enormous blades could lead to the 10+MW wind turbine

A new design for gigantic blades longer than two football fields could help bring offshore 50-megawatt (MW) wind turbines to the United States and the world.

Leading edge erosion phase II wind tunnel test begins

Sandia, through its Blade Reliability Collaborative, partnered with a wind turbine operator and associated wind turbine manufacturer to study the effects of blade erosion on wind turbine power performance.

Sandia Participates in the second annual Composites and Advanced Materials Expo

Sandia Wind Technologies Department materials lead, Brian Naughton, co-chaired a session with Shridhar Nath of GE Global Research on composite material applications in wind energy at the CAMX conference in Dallas.

SWiFT Restart Technical Review Committee Meeting

The SWiFT Facility passed a critical milestone towards a complete restart of operations with the approval to re-mount rotors and complete the commissioning.

National Rotor Testbed project builds a small research blade with a big wake

This article comes from Sandia National Labs Wind & Water Power News and is reposted with permission. A new wind turbine blade has been designed at Sandia National Laboratories for the National Rotor Testbed (NRT) project and for future experiments at the Scaled Wind Farm Technology (SWiFT) facility with a specific focus on scaled wakes.…

Sandia National Labs’ Structural Health Monitoring and Prognostics Management System reduces offshore wind O&M costs

Offshore wind energy could potentially play a significant role in helping the United States obtain an energy portfolio composed of clean, renewable, and diversified resources. One current obstacle to the utilization of offshore wind energy is that most projections put the operation and maintenance (O&M) costs of offshore wind farms between 2 to 5 times…

WEC-Sim leveraged to model floating offshore wind experiments

This article comes from Sandia National Lab’s Wind & Water Power news. The University of Minnesota and Sandia National Laboratories have partnered together over the past three years for the DOE funded offshore wind FOA on the high resolution modeling of offshore wind turbines and farms. In 2013, the University of Minnesota performed experimental tests…

Large-eddy simulation of SWiFT turbine array

This article comes from Sandia National Lab’s Wind & Water Power news and is reposted with permission. The total energy produced by a wind farm depends on the complex interaction of many wind turbines operating in proximity with the turbulent atmosphere. Sometimes the unsteady forces associated with wind negatively influence power production, causing damage, and…

16,000 tests on 500 composites now publically available

This article was extracted from the August issue of the Sandia Wind Research Newsletter and published with permission. Wind turbine blade growth continues to have the largest impact on energy capture and LCOE reduction. While the 40 to 45-m long blade is today’s mainstream segment, it is estimated that blades over 50-m long will be…

Sandia wake imaging system successfully deployed at the SWiFT facility

This article was extracted from the August issue of the Sandia Wind Research Newsletter and published with permission. The Sandia Wake Imaging System (SWIS) was deployed for a full-scale field demonstration at the Sandia Scaled Wind Farm Technology (SWiFT) Facility in Lubbock, Texas over the first three weeks of July 2015. The successful field-demonstration was…

Institute for Advanced Composites Manufacturing Innovation hold an inaugural members meeting

This article was extracted from the August issue of the Sandia Wind Research Newsletter and published with permission. Sandia Wind Department technical staff members Josh Paquette and Brian Naughton attended the inaugural members meeting for the newly formed Institute for Advanced Composites Manufacturing Innovation (IACMI) in Knoxville, Tenn. in June. A few hundred attendees from…