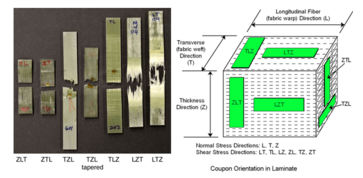

Tensile coupon failures are to the left while the block indicates coupon orientation indices and location in a thick laminate.

Sandia National Laboratories recently published “Analysis of SNL/MSU/DOE Fatigue Database Trends for Wind Turbine Blade Materials, 2010-2015” by researchers at Montana State University (MSU), a long-time academic research partner. Since 1989, Sandia has collaborated with MSU to test and report key data and trends related to fiber-reinforced polymers (composites) and other materials used to construct wind turbine blades. As of 2015, MSU researchers have compiled a public database of the results of over 16,000 tests on 500 materials and published technical papers explaining key trends.

The new report’s valuable insights from the past five years of wind-blade material testing will help supply-chain decision makers procure materials that improve the performance of wind turbine blades. The report includes the following topics:

- Details on experimental methods

- Static properties of thick laminates (the block in the figure)

- Impacts of fabric architecture and resin on tensile fatigue

- Creep and fatigue interaction in ±45° laminates

- Adhesive and core material fatigue

- Comparison of fatigue trends for various blade materials

- Environmental effects on composite laminate performance

The report’s supporting test data are freely available to meet industry needs. Download the latest database (v.24.0). Access related publications through Sandia’s Wind Program and the MSU Composite Technologies Research Group.

Filed Under: Blades, News