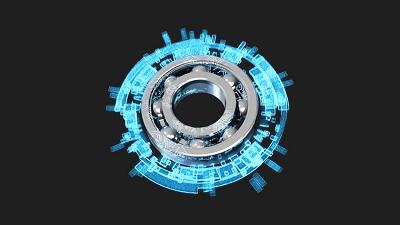

SKF Insight lets company bearings communicate their operating conditions continuously – with all the intelligence inside the bearing, including self-power, sensors, cables, and data-acquisition electronics.

SKF Insight introduces an innovation in “smart” technologies for integration into new SKF bearings. This technology lets SKF bearings communicate their operating conditions continuously – with all the intelligence inside the bearing, including self-power, sensors, cables, and data-acquisition electronics. This new integrated diagnostic technology can make condition monitoring more widely applicable, especially in applications where it was previously impractical or impossible. Ultimately, the technology provides greater control over the life cycle of machinery, leading to lower total costs while increasing reliability and machinery uptime.

SKF Insight technology monitors the conditions that can cause bearing damage from the first microscopic effect as it happens, letting users take remedial action to avoid increased damage in the bearing and prevent escalation. (Conventional condition monitoring measures parameters such as vibration and temperature, which indicate problems only after bearing damage has occurred.) In addition, by monitoring the load directly on the bearing, the technology can measure the load actually experienced by the bearing to determine the direct effect of any changes in operating conditions, which could potentially have an adverse effect on the bearing.

Among key features, SKF Insight includes miniaturization and packaging of sensor technologies to measure critical parameters such as rpm, temperature, velocity, vibration, load, lubrication, and others. The “smart” bearings can generate their own power for operation and intelligent wireless technology packaged inside the bearing enables communication within environments where traditional Wi-Fi cannot operate. Lastly, the bearings can form a “mesh network” to send information relevant to their condition for analysis.

SKF Insight solutions also include SKF Asset Diagnostic Services, which connect users to SKF industry application knowledge, a global network of SKF Remote Diagnostic Centers, global IT solutions, and makes all application data accessible in a single cloud-based system. This collective data reflects a huge breadth of knowledge and experience in diagnosing and solving machinery reliability issues in applications across all major industries worldwide. SKF Insight application-specific solutions are under trial with key industries, including wind energy, railways, and metals with others in development.

SKF USA Inc

www.skfusa.com

Filed Under: Bearings, News