Computational testing shows an overall gearbox life improvement by a factor of four fold.

How small data from material science accurately predicts failure rates and more

A big-data approach to predictive maintenance and failure rates can pose a challenge for operators to manage without the necessary infrastructure and trained personnel.

“Small data” from material-science models offers wind operators lower O&M costs than “big data” from CMS sensors

We have brought to the table a deep learning about the physics of actual componentry through material science. DigitalClone Technology stands apart from CMS thoughts small data ability to advance the O&M proposition from failure diagnosis to failure prognosis.

Sentient Science adds two more awards

Sentient Science has accepted a second major award in seven days. The Wind Dallas O&M Show honored Sentient with the Best Technological Innovation Award

Sentient Science takes $17 million in venture funding

Sentient Science, a leading provider of materials science-based life prediction and extension technology, today announced a significant working capital infusion to add new products to its Wind Turbine Operator Fleet.

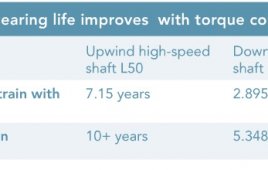

Gearbox model predicts longer bearing life with controlled torque reversals

RECENT PERFORMANCE MODELING of wind-turbine-gearbox bearings with field data suggests that taming torque reversals could lengthen a gearbox-bearing life up to two fold. The field data was collected by engineers at AeroTorque and supplied to bearing simulation and prediction firm Sentient Science. The later company has collected data on millions of military aircraft bearings and…

How is condition monitoring changing in the wind industry?

Unscheduled maintenance and turbine downtime are costly issues in the wind industry. Condition monitoring systems, or CMS, have provided one answer to help detect damage or component failures in turbine machinery often before they become serious problems. While wind-farm owners once considered CMS as a nice advantage, these systems are now becoming a necessity…

Prolonging turbine life with predictive software

Stephen Steen is the head of Industrial Internet Solutions at Sentient Science, a third-party solution provider for wind-farm owners, operators, and OEMs. The company recently developed a prognostics-based computational solution for wind farms, which lets turbine owners predict failures 90% earlier than by diagnostic approaches alone. In this Wind Talk podcast, Steen speaks to us…

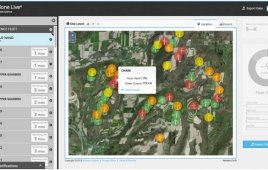

DigitalClone Live 2.0 now contains prognostic models to extend the life of GE 1.5 wind turbines.

Sentient Science has announced the release of DigitalClone Live 2.0. The software is a computational tool and condition-based monitoring service that helps companies predict and extend the life and performance of critical components in design, testing, procurement and service. DigitalClone Live was extended to meet the needs of the GE 1.5 owner operators in North America…