Trelleborg’s offshore operation will showcase NjordGuard, a cable-protection system for offshore wind cables, at the International Conference on Ocean Energy (ICOE 2018). Njordguard is an integrated protection system that protects offshore windfarm power cables in wind-turbine generators and offshore substation platforms. It features easy installation and high abrasion resistance. Its API 17L-certified Uraduct material enables…

Trelleborg exhibits cable protection system at Global Offshore Wind

One of the ways that Trelleborg has contributed to solving offshore wind challenges is in the development of NjordGuard, a cable-protection system for offshore wind cables.

Accelerating renewables development through knowledge transfer

By transferring oil and gas industry knowledge and expertise to renewable energy we can shorten the development time for new concepts.

Trelleborg successfully completes wet testing of NjordGuard

Trelleborg’s offshore operation has successfully completed a series of wet tests to verify the capabilities and functionality of its NjordGuard cable protection system.

Trelleborg introduces offshore wind cable-protection system

Trelleborg’s offshore operation recently launched its innovative protection system, NjordGuard, for the renewables’ market. The system is designed to protect offshore wind, power-cables in monopile and J-tube applications. “The way the industry thinks about energy and renewables has transformed and it is no longer just a concept but a reality,” said John Deasey, Renewables Sales…

Trelleborg demonstrates how its expertise offshore contributes to growth and performance of renewables

Trelleborg’s renewable Distributed Buoyancy Modules (DBMs) are typically used between structures and a surface vessel or platform.

Report from Trelleborg: Reaching a higher level of project maintenance

Despite short term trends such as low crude oil prices, no one is predicting the end of the offshore exploration and production industry. However, growth has slowed causing disruption to some projects and applying pressure to the supply chain at every level. With this in mind, the Next Level Report identifies ways in which the…

PTFE seal wins 2011 innovation award

Turcon M12, a PTFE-based material launched in 2011 by Trelleborg Sealing Solutions, has received a 2011 Innovation Award from Flow Control Magazine. According to the company, the PTFE-based sealing material has unrivaled performance in key hydraulic sealing characteristics such as friction, wear, and high-pressure operation. Testing shows Turcon M12 resistant to most media, including a…

Seal material for hydraulics good to 270°F

A proprietary polyurethane compound, Zurcon Z25, has all the characteristics of the widely used Zurcon grade Z20 with an elevated operating temperature to 130°C or 270°F. Zurcon Z25 is recommended for hydraulic applications in which high-temperature performance is required due to an improved extrusion resistance and compression set. The material is ideal for use in…

Seal material now rated for wider temperature range

The manufacturer of the sealing material Isolast J9440 says it has been improved with a higher operating temperature—up to +240°C —and it’s accredited to the USP Class 6 standard for use in medical and healthcare industries. Isolast J94440 has a continuous operating temperature range (from -7 to 240°C) and is compatible with most media. The…

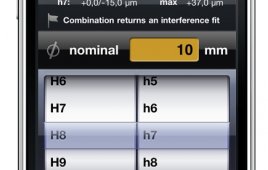

ISO fits and tolerances? There’s an app for that

An iPhone app, based on the ISO 286 System of Limits and Fits, “ISO Fits & Tolerances,” will help engineers cut time and let them work away from their desks for some tasks. ISO Fits & Tolerances is easy to use. After entering a nominal diameter, select the tolerance classes for bore and shaft. The…

The story below the first full-scale floating wind turbine

The innovative offshore floating Hywind wind turbine, moored in the North Sea off the Norwegian coast, demonstrates how Trelleborg Offshore’s syntactic foam buoyes contributes to the future of offshore power generation. “People see the tower and turbine, but forget that the expertise in designing the subsea portion is also critical, because it keeps the whole…

Tests show Trelleborg bearings wear exceptionally well at low velocities

Trelleborg Sealing Solutions’ Orkot® TXMM bearing material has proven to be one of the best in direct electric motor propulsion systems on ships. The motors operate at low shaft velocities and, subject to boundary lubrication, bearings used must demonstrate exceptional wear resistance. An extensive test program was conducted to prove Orkot® TXMM bearing material performance…

A super seal for temperature extremes

Isolast J9876, a recent perfluoroelastomer, provides the most comprehensive media resistance at elevated temperatures of any perfluoroelastomer on the market, according to its developer. Seals in this material, from Trelleborg Sealing Solutions, extend their life in aggressive, high-temperature environments at an optimized cost-to-performance ratio. Equipment suppliers and process managers benefit from the advantages of a…

Bearing handles rocking platforms

A heavy-duty flexible bearing or bushing combines a high-load capacity with an ability to accommodate torsional and angular movements in all planes without lubrication or metal-to-metal wear. The Spherilastik Bearings come in center bore or as a solid member depending on how it’s attached. Typical uses include equipment in wind turbines, traction and braking reaction…

Teeter bearing help wind turbines Sssssssh

A few early wind turbines in the U.K. drew considerable criticism because they were noisy, So Wind Energy Group Ltd. (WEG) paid more attention to acoustic isolation in the recent MS-3 turbine. The primary noise-attenuation feature was a Metalastik Spherilastik “teeter” bearing from Trelleborg Industrial AVS. The bearing acts as a resilient spherical joint. In addition,…