John Yan, China, sawt.com

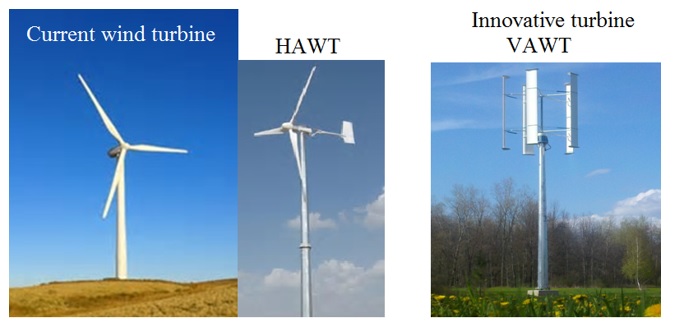

Most wind turbines fall into one of two general categories: horizontal axis and vertical axis. Each can be further divided into small and large wind turbines.

Wind turbines can be classified as utility scale and small scale and then into a horizontal axis (HAWTs) and vertical axis versions (VAWTs).

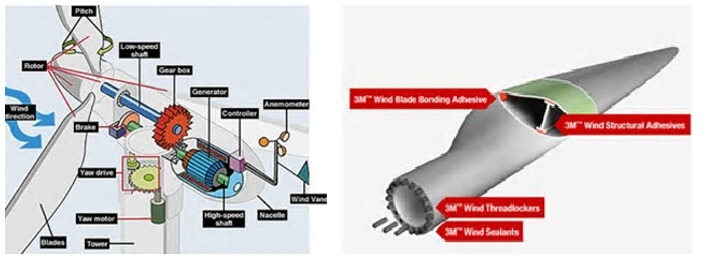

The technology for traditional horizontal axis wind turbines (HAWTs) have been in development for more than a hundred years. This technology includes blades and their manufacturing, gear boxes and their manufacturing technology, pitch angle devices and their technology, and so on. The technologies are very mature. Betz’s Law, which defines the maximum amount of energy that a HAWT can extract from the wind, is based on a single disk (the rotor) moving in a two-dimensional space.

- Small vertical axis wind turbines

Small vertical axis wind turbines differ greatly from middle to large vertical axis ?? wind turbines because a blade’s driving force and direction are different when a blade rotates. At some position, the blade force is big and the direction are positive. At some positions, the driving force will be smaller and also positive. But at other positions, the driving force and direction are negative, and big and small. Also, as the rotor diameter is made bigger, the negative forces become larger. So if the diameter of rotor is made larger, the blade’s angle (pitch) has to be adjustable in real time. This is called “real time attack angle control regulation” technology.

1.1 Most current vertical axis wind turbines have three major problems:

- Low-power generation performance

- They work in a narrow range of wind speeds and brake frequently, thus reducing their power output

Poor stability when rotating shortens the turbine life.

1.2 Solving the three problems

The SAWT, a vertical axis design, solves the three technical problems in the vertical axis wind turbine industry. One designer has produced a small vertical wind turbine that sold over 4,000 units in around 60 countries since 2007, and used patents to set up technical barriers.

1.3 How to design a good small vertical-axis wind turbine

1.3.1 Although different from a HAWT, the core technology of a VAWT remains a wind mill structure with blades. After choosing an airfoil, it is necessary to calculate a concave orientation, angle, width, and quantity because each of these factors determines the performance of the VAWT.

So a first step is to choose a low-speed airfoil. A second step puts the concave orientation to outside, a third step chooses a small blade angle (8° works well) and a suitable blade width. The best blade quantity is five. And then the blade connection method is important. It’s best is to use socket structure for easy installation and reduced the drag forces. These factors determine the power generation performance of the VAWT.

1.3.2 A HAWT turbine must yaw − redirect itself into the wind − but the VAWT need not. So VAWTs muse use the “positive pitch attack angle regulation”. This feature uses centrifugal force to control the blade angle when the rotation speed exceeds the rated speed.

1.3.3 A good vertical axis wind mill has to remain stable when it is spinning it. If not, the turbine will “shake its head” when the rotor is turning. That will reduce the turbine’s life and cause other problems such as noise and mechanical wear. So the best solution is to use a coaxial structure for the wind mill and generator. The coaxial arrangement of wind mill and generator ensures a reliable seal, safety and stability, free of mechanical noise, a reasonable bearing for windmill, and a long useful life.

1.3.4 Damage may occur to wind turbines when the wind speed exceeds 25 m/s. So vertical axis wind turbine needs an automatic brake system. As a wind turbine starts to brake, it must overcome the rotational inertia and the driving force from the wind. So a good design calculates the torque in the rotor at survival wind speed and chooses a suitable disk brake for that amount of energy.

2. Medium & large VAWT technologies

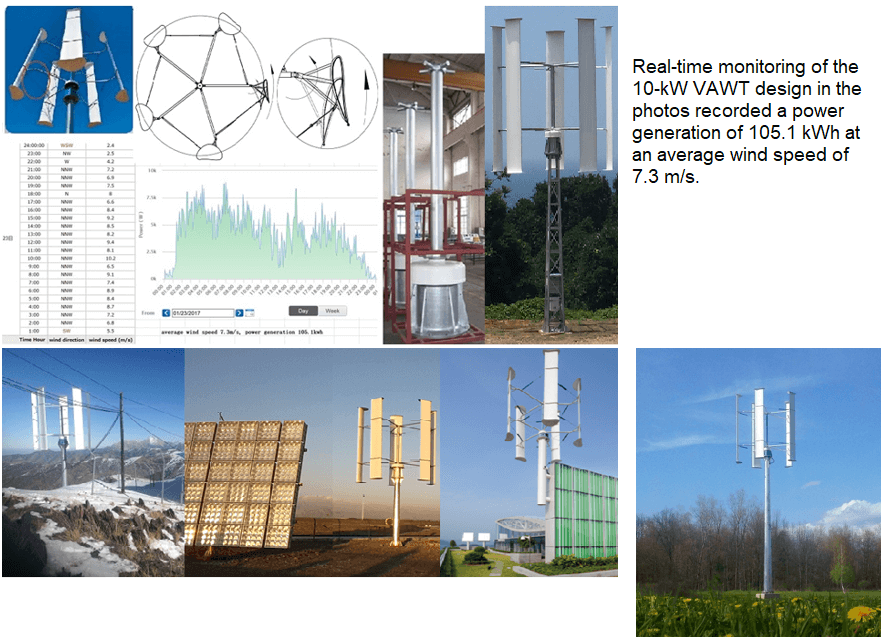

Though many other turbine manufacturers are developing medium and large VAWT, they have adopted the design approach from small VAWTs by simply proportionally enlarging a small turbine to become a “medium or large VAWT”. They do not truly understand the characteristics of a VAWT.

It is well known that a VAWT is quiet, safe, and does not need a tall tower. However, hardly any commercialized large VAWT have been launched despite of the efforts of countless engineers. The reasons are obvious: the problems of aerodynamic efficiency, self-starting, structural stability, and safe braking remain unsolved. The problems have to be solved for any type of wind turbine.

These three problems are solved with “active real-time pitch attack angle regulation” and “Truss Structure Shaft” technologies.

2.1 “Active real-time pitch attack angle regulation” technology

The core of this technology is to adjust blade angles on a spinning turbine. The device was tested on a 1-m tall x 1.36-m wide VAWT in a wind tunnel at a wind speed of 2 m/s. The measured torque was 0.9 to 1 Nm at 44 rpm. The conversion rate of wind energy to mechanical energy reaches 68%, surpassing the limit of 59.3% by Betz Law. This is not to say the Betz law is wrong. In this theory, a HAWT uses a single disk rotating in a two-dimensional space while the VAWT is a multiple disk rotation in a three-dimensional space. This makes the VAWT equivalent to two HAWTs.

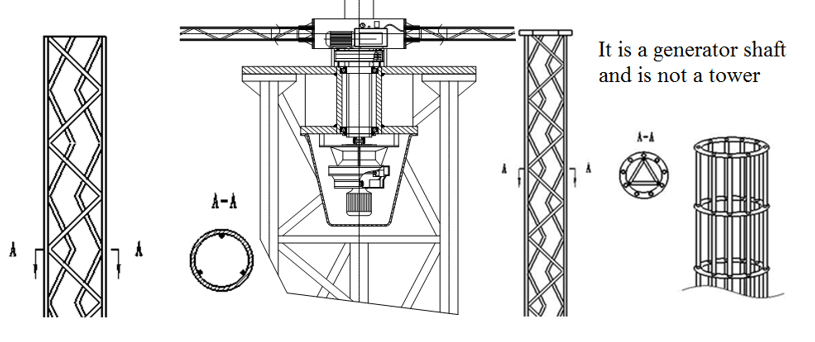

2.2 Truss structure for the main shaft of a large VAWT

The bending moment on the wind mill can be extremely large when the rotor diameter is sufficiently large. That means the main shaft must have a large and strong diameter, which makes commercialization more difficult. Our solution uses a hollow truss as a main shaft inside because the truss structure is strong and relatively light, meeting the requirements for the main shaft on medium and large VAWTs, as well as the demand for commercialization.

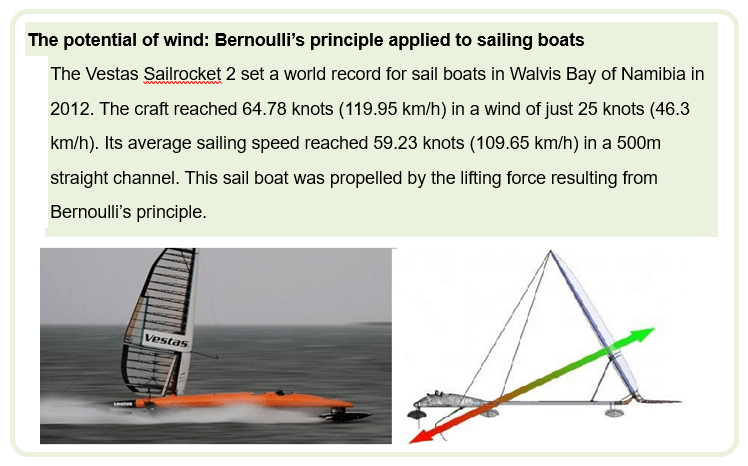

The potential of wind: Bernoulli’s principle applied to sailing boats

The Vestas Sailrocket 2 set a world record for sail boats in Walvis Bay of Namibia in 2012. The craft reached 64.78 knots (119.95 km/h) in a wind of just 25 knots (46.3 km/h). Its average sailing speed reached 59.23 knots (109.65 km/h) in a 500m straight channel. This sail boat was propelled by the lifting force resulting from Bernoulli’s principle.

3.1 Problems with traditional designs

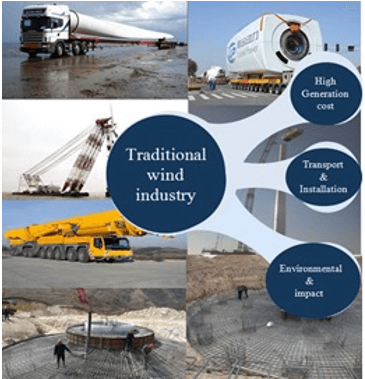

Some will argue that the pain points of traditional wind turbine Industry include:

- Often a high power generation cost than traditional energy

- Manufacturing is complex

- Large parts are difficult to transport

- A foundation that requires a large volume

of concrete and rebar. - Installation requires complex and costly cranes

- Noise pollution

- Damage to the ecosystem

- Chemical pollution is possible

- High voltage generates electromagnetic radiation and interference

A solution: The Super Turbine and how it works

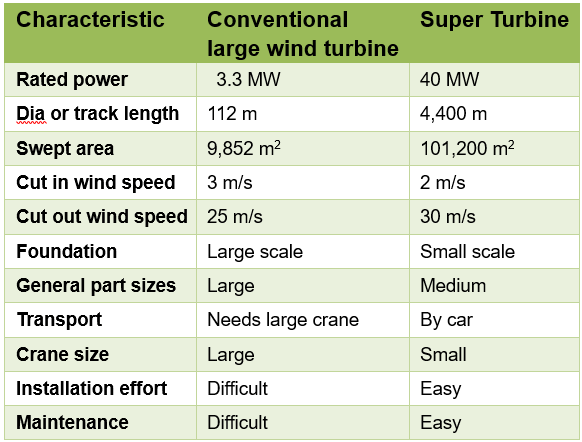

Over ten years of R&D in the VAWT industry has led to the Super Turbine, a type of large wind turbine. The Super Turbine, developed by 2014, has low power-generation costs, and easy installation and maintenance. At its core is an extension of the “active real-time pitch attack angle regulation” technology which has been verified by experiments. We think it could lead a revolution in current large, wind-turbine industry.

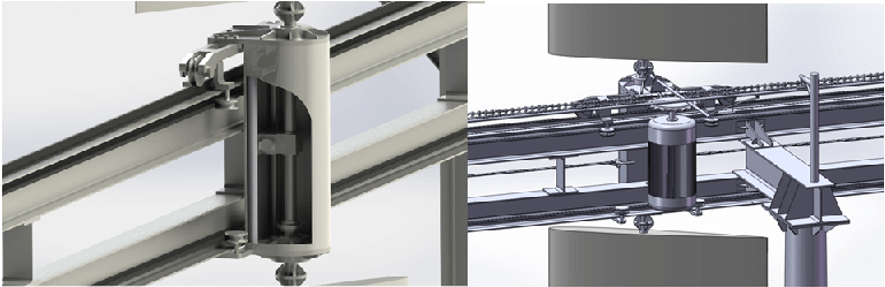

- To produce power, hundreds of blades are moved along a track by lift forces and transmitted through a chain to drive hundreds of generators fixed on the circular track.

- Active real-time pitch angle regulation technology monitors the wind direction, speed, and the position of each blade on the track. Then it adjusts the blades’ angles to gain the maximum lifting force. In this way the Super Turbine can enhance the wind energy conversion rate and enable the generation of high power.

- A single Super Turbine can be designed to fit a wind farm’s conditions and customer requirements. A turbine can be sized from 7 to 50 MW.

3.3 The technologies verified by wind tunnel tests

The design is an extension and further application of “active real-time attack angle regulation” technology. In a circular orbit, driven by the wind, the blades at different locations will produce the driving force with different magnitude and direction.

A modified track has additional advantages. For instance, where the driving force is greatest, cut the circular track at this location and extend it into a straight line, which is a prototype of super turbine. Like a sailing boat, it is fastest in a straight line.

A super turbine could be designed round, long, or even triangular shape, but the turning radius is the same according to land and wind conditions.

3.4 Features of Super Turbine

The design uses current mature technologies for all parts. Major components include:

3.6 Lower equipment costs

- Super Turbine use current and mature technologies, such as that for motion control, hydraulics, tracks, and moving power. So it will be easy to manufacturer.

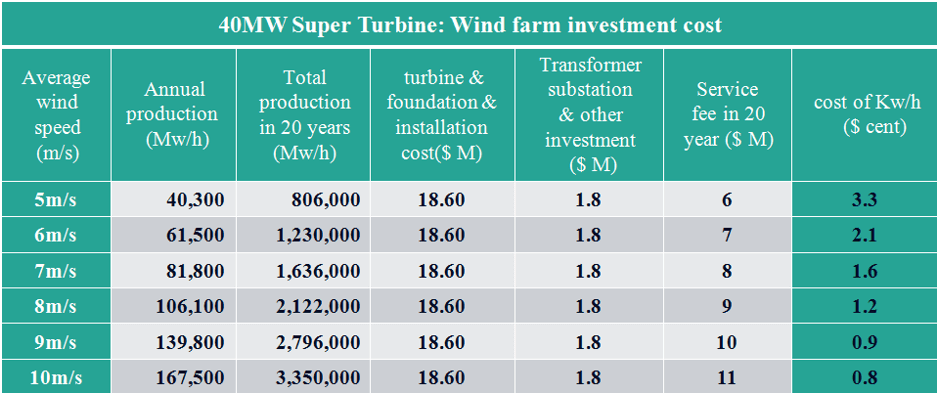

- A 40 MW Super Turbine user total cost is $15 million, or $0.38 per watt.

Because of these advantages, the design will change the shape of current large wind turbine industry. The design simplifies the manufacturing of large wind turbines because it does not need large blades, large gear boxes, large generators, or huge towers.

Filed Under: News

I am currently contemplating a project to retrofit big blocks of apartment buildings around Europe (god knows there are tons too many of them) with renewables – wind power on top of the list. The wind power generating source must be a vertical axis (due to limited space and other reasons) type and we plan to use them exploiting the wind shear effect observed around the edges of such buildings – with some help in the form of special curvy sail-like aprons/valves to channel winds in one direction/bottleneck area. Please do let me know if you think you have a good tech approach to recommend.

Hello, I’m not sure of the design type “Tesup Atlas 2.0” is the make and model. It has a 11m/s start (48 volt model) is what I’m looking at, primarily for my garage for lighting, in an urban setting but hoping to use it in combination with solar on my boat. Thoughts? Mark

The offshore sailing community is screaming for a noiseless efficient dc power source that can contribute to solar negative attributes. I am also amount those persons. I would invest in a vertical wind generator compact enough and made for marine applications. I would hope my country (USA) would have talented people who could produce a design to be produced? I would invest in such company if reusable.

Do you suppose it’s possible to build one for marine applications?

combining a flywheel with a wind turbine can only be done with a vertical axis.

Doing this on a large scale has dramatic implications. It can not be done with existing designs but it can be done with the concept shown on http://www.maxwindpower.com and that makes it possible to reduce carbon emissions by using more wind for power production.

It seems to me that VAWTs are more bird friendly. That alone would be reason enough for investment. Aside from the the mega generator,? I wonder if the researchers have ever considered some sort of framework that the VAWT could be mounted in. This would potentially eliminate any wobble or unwanted vibration.

Bottom line, keep doing the research! Thar she blows!