EWT's direct drive wind turbine needs no gearbox or speed increaser. The large disc is the generator.

Most utility-sized wind turbines use a costly speed increaser to drive a generator. Netherlands-based Emergya Wind Technologies (EWT) however, builds wind turbines based on a direct-drive (gearbox free) design. The company says its turbine offers improved performance and reliability over conventional wind turbines.

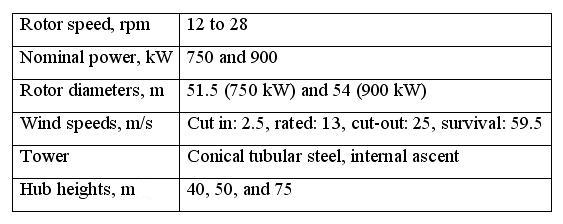

The company’s main product is a 900 kW, pitch controlled variable speed wind turbine. The unit builds on over ten years of operational experience with the company’s 750-kW turbine, of which over 200 units have been installed. A future challenge, says the company, is to develop large wind turbines in the multi-MW range for onshore and offshore cites.

EWT’s 900-kW design uses a multi-pole ring generator that rotates slower than conventional designs, for long life. An autotransformer, which sits between the generator and a power converter, reduces the voltage to 690V. This is standard in the wind industry.

The generator operates at a varying frequency, directly proportional to the rotor speed. The converter modifies this variable frequency output to a fixed frequency corresponding to the grid frequency, 50 or 60Hz. This arrangement, according to one consulting firm, is now finding favor with many manufacturers of multi-megawatt turbines.

This design replaces a complex high-speed geared drive train common in most conventional wind turbines. To further reduce the number of rotating components, a large single main bearing (three row, cylindrical-roller unit) carries the rotor assembly and generator rotor, to reduce the number of rotating components. A monocoque main chassis gives easy service access to essential rotor hub internals, such as rotor-blade-pitch drives and back-up batteries.

The turbine feeds generator power into the grid by means of a ‘back-to-back’ (ac to dc to ac) type full-converter equipment. This converter has several programmable functions such as a capability to limit output during night hours and a noise reduction feature. Built-in grid-fault-ride-through technology is available on demand. The company says the features make the design well suited to solitary applications, weak grids, and high-turbulence sites. EWT says it operates in compliance with ISO 9001:2000 and is VCA** certified, one that tests safety control systems of servicing companies in an objective and structured way. It is comparable to OHSAS18001. The table lists a few specs.

Filed Under: Gearboxes, Generators

hello sir, i congrates you for your work,intrest in wind power. sir am doing M.E. my wish is to do the project in wind power using power electronics. i select one paper(using Direct Drive concept),but sir i have doubt in moduling of Wind turbine, please give some guidlines about Wind turbine moduling.please sir…

This article is very easy to understand and useful.

Thanks!

DEAR SIR,

WE WANT TO PUT 5 NOS X 1 MW WIND MILL IN NEPAL. PLEASE GUIDE US HOW TO PROCEED, WE SHALL SELL THE ELECTRICITY TO GOVERMENT OF NEPAL.

RAGHU