The performance degradation of old wind-farms and decreasing incentive tariffs across Europe for the new projects disappoint small independent wind-farmers. At the same, time large players target asset consolidation to secure long-term portfolios requiring longer asset life-cycle and enhanced returns. Operators can opt for several alternatives to improve projects or assets value.

One option is to repower their wind farms by refurbishing the entire turbine. This process can be expensive and difficult due to strict constraints regarding an environmental impact assessment, turbine height, power limitations, grid connection limitations, and lengthy and complex permitting procedures. In addition, turbine OEMs are focusing on developing and selling new products rather than improving the performance of older assets.

Many older turbines cannot be refurbished because of technology shifts or manufacturing capacity of the suppliers is saturated by the new lines.

In other cases, due to the consolidation wave that occurred in the past decade, turbine manufacturers do not have in-house resources to restart the production of molds and the manufacturing of the older products.

In other cases, due to the consolidation wave that occurred in the past decade, turbine manufacturers do not have in-house resources to restart the production of molds and the manufacturing of the older products.

Another option is to substitute only selected components, such as converters and alternators. This option is already ongoing worldwide at old wind-farms, while the replacement of blades and rotors is only considered when a blade breaks or experiences heavy damages. Furthermore, when components are replaced by like new equipment, the turbine is only able to improve to the original performance level.

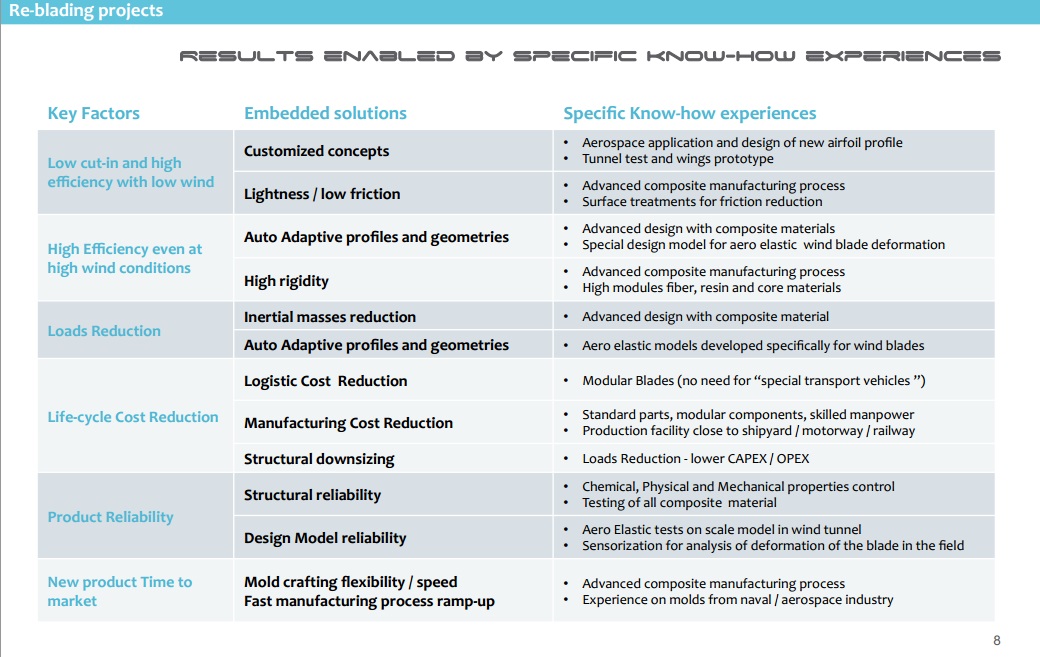

There is another option. The business idea proposed by eTa Blades is to introduce innovative turbine-blade designs that couple industrialization with manufacturing competences. This targets a superior performance by reverse engineering the original blade, which giving customers an extended asset life and enhanced returns. Customers value the performance improvements provided by new blades so features and pricing mechanisms are based on superior quality, which delivers better than original performance.

The company, eTa Blades, designs, develops, and manufactures innovative wind blades and supports re-blading programs for the needs of the next generation wind farm, enhancing the value of assets (versus lower or no incentives) while improving wind farm efficiency (versus market saturation) at a lower environmental impact (versus the. deteriorated social acceptance).

Different competences, coming from our top management and an entrepreneurial experiences in wind, marine, and aerospace, lead with our partners, are joined together to craft new blade profiles, use advanced materials, adopt innovative technologies driving the efforts towards overall wind farm efficiency improvement.

The company ss its vision is to provide:

- more power from less windy sites while maintaining high efficiency when the winds blow strong.

- significantly improved output from old wind-farms thereby providing longer life-cycle

- a load reduction on blades, gearboxes, and tower under any wind condition thanks to advanced manufacturing techniques and design methods that allow for self adjusting bend-twist and passive deformations.

- the ability to seamlessly support our clients from start to end, from designing a new blade suitable for their original equipment and site conditions, through to authorization procedures and investment decisions

In other words, the designs are said to provide a significant cost reduction ratio ($/kW) for wind turbines and improved wind-farm returns. The company brochure is here.

Filed Under: Blades, News, O&M

Good morning and thanks for the comment – can you please expand a bit on the concept to ease our answer?

Apparently eTa Blades hasn’t looked at the Enercon, GE, Vestas, Siemens and Mitsubishi patents on winglets.