There is plenty of room for improvement in operations and maintenance activities. James Parle will tell how a team from Muir Data systems developed a system that lets wind tech report more thoroughly on their activities with easy-to-use portable devices. And Grant Leaverton will report on how unmanned aerial vehicles can provides high resolution images…

Webinar – Leading Edge Erosion: Protection, Costs, and Benefits

This discussion will focus on the application of Wind Turbine Generator (WTG) Leading-Edge Blade Coatings to prevent blade degradation that decreases the performance of the WTG. We will explore the root causes of the blade erosion cycle and the effect of the leading edge erosion in the WTG performance output. Next, we will provide information…

Keeping turbines and workers safe with lightning diverters and electric meters

High current is a hazard to the turbine and technicians alike. For the turbine, lightning strikes can damage blades and short out electric equipment when not sufficiently grounded. There are ways to handle the high current in lightning. Inside the nacelle, technicians have to diagnose issues to get troubled turbines back into production as soon…

Webinar: Day-to-day condition monitoring for a large fleet of wind turbines

This webinar describes some of the challenges faced when monitoring a large fleet of wind turbines. Factors such as different turbine and gearbox types, different condition monitoring systems (CMS), geographically dispersed sites and variations in maintenance practice all make the job of a monitoring engineer a difficult task. Romax utilize in-house software called InSight Fleet…

Webinar: An Engineer’s Guide to OSHA’s New Recommendations for Arc Flash Studies

There are several calculation methods available to calculate arc flash risk in terms of incident energy, but until recently, there was no clear direction from OSHA about which calculation method was preferred. Because of this, several methods were used. The new final ruling of OSHA 29 CFR Parts 1910 and 1926 provides recommendations for calculation…

Webinar: The Value of SCADA Infrastructure Virtualization on Wind Farms

Wind farm owners and operators are beginning to realize the need for managing the critical infrastructure of their wind projects. They are confronted with several challenges including expired OEM warranties, software vendors dropping support for their products that have reached end of life, and higher protection requirements from the security sector. In order to meet…

Webinar: Transient Wind Events and Their Effect on Drivetrain Loads

Although wind turbines have been around for decades, recent research has been focused on what occurs in wind turbines under abnormal wind conditions. It is understood anecdotally that high gusts and turbulent winds can add to the chance of breakdown of wind turbine equipment and lead to an increase in O&M and capital costs. Why is…

Webinar: Basics of the Power Inverter

This webinar from PSI Repair Services will present the basics of power inverters. The presentation will discuss the purpose of inverters, how they work, and where they are used. Attendees will learn of the main components in power inverters and how they affect operation. Basic design criteria and common failure modes will also be addressed.…

Webinar: New Ideas for Repairing Gearboxes and Generators

Wind-turbine-gearbox and generator failures have been a challenge to the wind industry for years, but engineers at companies that design, refurbish, and study them say they have a handle on the real causes of the failures and how to repair them. Some research has focusing on oil contamination, shock loads, and heat as a few…

Webinar: Following the Wind Turbine Condition-Monitoring Circle

Live webinar is Tuesday, July 22 at 2 PM Eastern. Data from a Condition Monitoring System (CMS) in a wind turbine travels to the analyst, then to purchasing and O&M, who then sends it back to the wind turbine with a technician who will perform some action. You can see that CMS data affects many…

Webinar: Wind Drivetrain Bearing Reliability

The bearings in a wind turbine drivetrain are the critical mechanical components whose failure most frequently causes costly downtime and repairs. Knowing the most common bearing failures is critical to successful wind plant operation. Understanding why wind turbine bearings fail will prepare you to make the right decisions when these costly failures occur, and reduce…

Webinar: Planning for Substation Maintenance and Reliability

It can be difficult to determine exactly what is needed to properly plan preventative and routine substation maintenance. Owners and contractors must work together to ensure a successful outage period during maintenance. Properly planning substation maintenance is key in reducing outage downtime. In this webinar, Chris Petrola of Acciona Energy and Paul Idziak of Shermco…

Webinar: Compliance and safety in confined spaces for the windpower industry

Windpower technicians encounter confined spaces every day. At work, technicians are sometimes required to use chemicals or special equipment in small areas that could prove hazardous. How do you ensure safety when air or space is limited? In this webinar, Rob Siegel of ENSA North America and Scott Bramlett of EDF Renewable Services discuss ways…

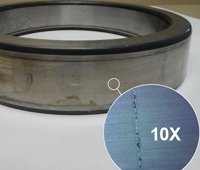

Webinar: Understanding the Root Causes of Axial Cracking in Wind Turbine Gearbox Bearings

Modern wind turbines are an important piece of our energy mix. Unfortunately, gearbox life issues have impacted their financial payback. Axial cracks in bearing raceways have become the major cause of premature gearbox failures in the latest generation of wind turbines; shortening life to as little as 1-2 years once it is initiated. Axial crack failures in gearbox…

Webinar: Improving Efficiency – Wind Forecasting and Assessment

As more wind energy is added to the grid, the inclusion of a weather measurement system to a wind farm is critical to ensure it meets financial and performance expectations. The data collected through the use of wind forecasting and wind resource assessments can detect turbine underperformance, decrease weather uncertainty, and predict wind farm productivity.…

Webinar: How to Reduce Expenses With Uptower Gearbox Repair

At a potential cost of $250,000 to $300,000 or more for a down-tower project, the repair of a wind turbine gearbox is one of the most costly expenses wind farm owners and operators face. Now, there is a better, more cost-effective way to give new life to gearboxes. Combining in-field service experience and precision gearing…

Webinar: New Ideas for Replacing Unavailable or Obsolete Power Electronics in Turbines

A few essential turbine components are just not available from OEMs. One example: Xantrex Matrix Inverters for GE 1.5 MW turbines. Without the inverter, power from the turbine cannot be applied to the grid. But there is still a reliable source for the unit. In this webcast, learn how electronics obsolescence in the U.S. wind…

Windpower Operations and NERC Compliance

Entities registered as a NERC Generator Operator (GOP) are responsible for complying with 39 NERC non-cyber security requirements regardless of who is performing the work. Requirements are grouped into standards, and then categories. The categories include Critical Infrastructure Protection (CIP), Communications (COM), Emergency Preparedness and Operations (EOP), Interconnection Reliability Operations and Coordination (IRO), Protection and…